Setting the right amperage for a 7018 1/8 welding rod is one of those details that can make or break a weld, and it’s something that caused plenty of frustration early on in my welding journey. Too little heat and the rod wants to stick, leaving a cold, ropey bead with poor fusion; too much amperage and you’re dealing with undercut, spatter, and weakened welds.

That’s why a reliable 7018 1/8 welding rod amperage chart matters so much. Amperage ties directly into metal thickness, joint prep, and arc control, especially when you’re laying structural welds where strength and safety count.

Unlike MIG vs TIG welding, stick welding with a low-hydrogen filler rod like 7018 demands precise settings for consistent results. Stick around, and I’ll break down the real-world amperage ranges and tips that help you weld cleaner, stronger, and with confidence.

What Makes the 7018 Rod a Shop Staple

Let me tell you, the 7018 rod isn’t just another electrode – it’s the reliable buddy I reach for when I need low-hydrogen performance on mild steel. It’s designed for all-position welding, except vertical down, and it excels in applications where strength and crack resistance are non-negotiable. Think pressure vessels, bridges, or even ship hulls; I’ve used it on all of those.

The “70” in 7018 means it has a minimum tensile strength of 70,000 psi, which is plenty for most structural jobs. The “1” indicates it’s good for all positions, and the “8” tells you about the low-hydrogen coating with iron powder for better deposition. That coating is what makes it sensitive to moisture – store them in a rod oven if you’re serious about avoiding hydrogen cracking.

In my experience, the 1/8″ diameter strikes a sweet balance. It’s thick enough for good fill on thicker materials but not so bulky that it overwhelms thinner stock. I’ve run it on everything from angle iron frames to repairing excavator buckets, and it always delivers if you respect its needs.

Decoding the 7018 1/8 Welding Rod Amperage Chart

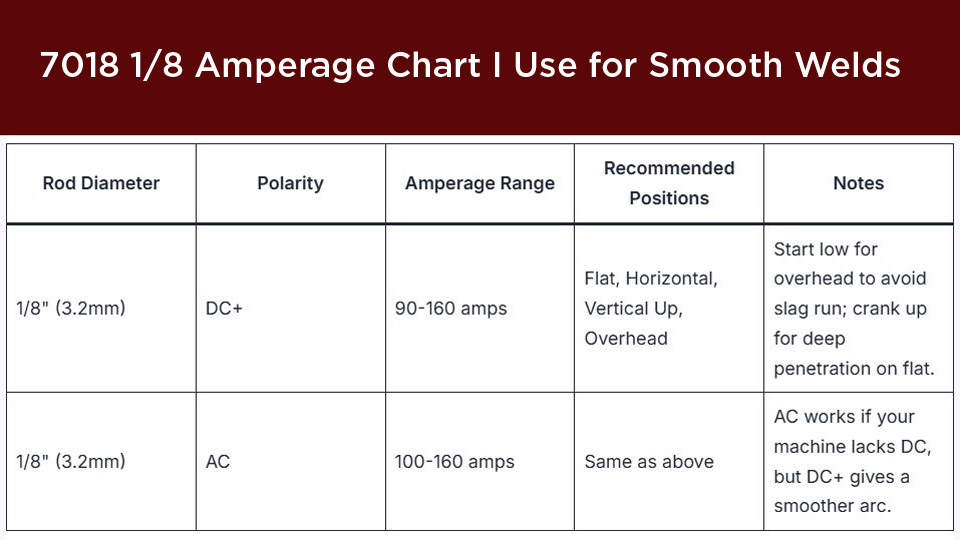

Let’s get to the meat of it – the amperage chart for your 1/8″ 7018 rods. I’ve put together this based on years of trial and error, plus what works consistently on machines like my old Lincoln SA-200 or newer inverter setups.

Remember, these are guidelines; always test on scrap first because your welder’s output, the rod brand, and even the weather can tweak things.

Here’s a straightforward table for quick reference in the shop:

| Rod Diameter | Polarity | Amperage Range | Recommended Positions | Notes |

|---|---|---|---|---|

| 1/8″ (3.2mm) | DC+ | 90-160 amps | Flat, Horizontal, Vertical Up, Overhead | Start low for overhead to avoid slag run; crank up for deep penetration on flat. |

| 1/8″ (3.2mm) | AC | 100-160 amps | Same as above | AC works if your machine lacks DC, but DC+ gives a smoother arc. |

For example, on 1/4″ mild steel in the flat position, I usually start at 120-130 amps. That gives me a nice, fluid puddle without burning through. If I’m welding vertical up, I’ll drop to 110-120 to keep the slag from dripping into my boots – been there, and it hurts.

Matching Amperage to Metal Thickness

One common question I get from new guys is how amperage ties into the material you’re welding. Too low, and your weld beads up like a rope without fusing properly; too high, and you’re blowing holes or warping the piece.

For 1/8″ 7018, here’s how I break it down by thickness:

Under 1/8″ thick: Stick to 90-110 amps. Great for sheet metal repairs, like patching a truck bed. Use short arcs and quick travel to avoid distortion.

1/8″ to 1/4″: 110-140 amps. This is the sweet spot for most hobbyist projects, like building gates or frames. I’ve welded miles of this on farm gates, and 125 amps is my go-to for solid penetration without excess heat.

1/4″ to 1/2″: 130-160 amps. For heavier stuff like I-beams or equipment bases. Multi-pass if needed; preheat if it’s cold out to prevent cracks.

Over 1/2″: You might need multiple passes or a larger rod, but 150-160 amps works for the root pass. I’ve done this on crane booms, and controlling heat input is key to avoid stressing the metal.

Always consider joint type too – a butt joint might need more amps for full penetration than a lap joint.

Polarity and Machine Settings for Optimal Performance

Polarity matters big time with 7018. I always run DC electrode positive (DCEP) for deeper penetration and a stable arc. It’s what I used on pipeline jobs where every weld had to be X-ray perfect.

If your machine is AC-only, like some older buzz boxes, bump the amps up by 10-20% to compensate for the less consistent arc. But honestly, if you can swing it, get a DC machine – it changed my welding game back in the day.

Don’t forget voltage; most stick welders auto-adjust, but if yours has controls, aim for 20-25 volts to keep the arc crisp.

Factors That Influence Your Amperage Choice

Amperage isn’t set in stone; it’s influenced by a bunch of real-world factors I’ve wrestled with on job sites. Let’s break them down so you can adjust on the fly.

Welding Position and Technique

Flat welding? You can push higher amps for faster deposition – I’ve clocked in at 140 amps on table work without issues. But overhead? Drop it to 100-120 or you’ll fight gravity and end up with inclusions.

For vertical ups, use a weaving motion and keep amps moderate to build shelf-like beads. I once had a whole section reject because I ran too hot vertically, causing undercut that weakened the joint.

Technique tip: Maintain a 15-20 degree drag angle, and whip the rod slightly for better slag control. Practice on scrap – it’s cheaper than redoing a job.

Material Type and Condition

7018 shines on clean mild steel, but if it’s rusty or painted, crank amps up 10-20 to burn through contaminants. I’ve dealt with oily parts in auto shops; a quick grind helps, but higher heat saves time.

For alloy steels, stick to the lower end to avoid cracking. And always match the rod to the base metal’s strength – no sense using 70k rod on 50k steel.

If the metal’s cold, like welding outside in winter, preheat to 100-200°F. I’ve skipped this and paid with cracked welds on thick plate.

Rod Storage and Handling

Low-hydrogen rods like 7018 hate moisture. I keep mine in a heated rod oven at 250°F; if yours have been sitting out, bake them at 300°F for an hour before use.

Damp rods? You’ll see porosity like Swiss cheese. I’ve thrown away batches after a humid garage storage mistake – don’t be me.

Common Mistakes with 7018 1/8 Rods and How to Fix Them

I’ve seen – and made – plenty of screw-ups with these rods. Here’s the lowdown to keep you out of trouble.

Running Too Hot: Signs and Solutions

If your arc is sputtering and the rod’s glowing red-hot, you’re over-amping. This leads to wide, flat beads with undercut edges that can fail under stress.

Fix: Dial back 10-20 amps and increase travel speed. On a recent trailer repair, I started at 150 and dropped to 130 for perfect fusion.

Running Too Cold: Porosity and Lack of Penetration

Cold welds look stacked and don’t tie in well, risking weak joints. Common on thicker stock if you’re timid with the dial.

Solution: Bump amps up and shorten your arc length to 1/8″. Test with a fillet break – if it snaps clean, you’re good.

Slag Inclusions and How to Avoid Them

Slag trapped in the weld? Usually from poor cleaning between passes or wrong angle.

Pro fix: Chip and brush thoroughly after each pass. I use a chipping hammer and wire brush religiously – saved me on multi-pass beams.

Arc Starts and Stops

Hard starts? Your amps might be low, or the rod’s damp. Strike like a match, and if it sticks, tap it free gently.

For stops, backstep into the crater to fill it and prevent cracks. I’ve had craters crack on pressure-tested pipes – not fun.

Step-by-Step Guide to Welding with 7018 1/8 Rods

Let’s walk through a basic setup, like welding a T-joint on 1/4″ plate – something I do weekly in the shop.

- Prep the joint: Bevel edges at 30 degrees, clean to bare metal with a grinder. No contaminants mean better welds.

- Set your machine: DC+, 125 amps to start. Clamp the ground close to the work for a stable circuit.

- Strike the arc: Hold the rod at 70-80 degrees, drag it back to start the puddle.

- Weld: Travel at 6-8 inches per minute, weaving slightly for wider beads. Watch the puddle – it should be oval, not round.

- Clean: Chip slag while hot; it pops off easier. Inspect for defects.

- Multi-pass if needed: For thicker joints, layer up, cleaning between each.

I’ve used this on countless repairs, from ATV frames to shop benches, and it holds up.

Pros and Cons of Using 7018 1/8 Rods

Like any tool, 7018 has its ups and downs.

Pros:

- Excellent strength and ductility for critical welds.

- Smooth arc, easy slag removal.

- Versatile for positions and applications.

Cons:

- Sensitive to moisture – requires proper storage.

- Slower deposition than some rods like 6010.

- Higher cost, but worth it for quality.

In my book, the pros win for most structural work.

Alternatives to 7018 When It Doesn’t Fit

Sometimes 7018 isn’t ideal. For deep penetration on dirty metal, I switch to 6010 – runs hotter, 75-125 amps for 1/8″.

For easier striking on AC machines, 6013 at 90-130 amps is forgiving for beginners.

If you’re MIG welding instead, ER70S-6 wire at 150-200 amps mimics 7018 strength but faster.

I’ve swapped to MIG on production runs for speed, but stick wins for portability.

Safety First: Protecting Yourself on the Job

Welding’s no joke – fumes, UV, heat. I always wear a respirator for 7018 fumes, which can be nasty.

Full leather gear, auto-darkening helmet (shade 10-12), and gloves. I’ve burned holes in cheap gloves; invest in good ones.

Ventilate your space – I use fans in the garage to avoid buildup. And never weld galvanized without precautions; that zinc smoke is brutal.

Real-World Applications and Case Studies from the Field

Take a bridge repair I did last year: 1/2″ gussets with 7018 at 140 amps, multi-pass. Held up through floods.

Or a DIY gate: 1/8″ tube at 110 amps, vertical. Smooth beads, no warpage.

In fab shops, it’s standard for ASME work – reliable every time.

Advanced Tips for Pro-Level Welds

For X-ray quality, use stringer beads at lower amps.

On overhead, short arc and low amps prevent drips.

Mix with 6010 root for hybrid strength.

I’ve refined these over jobs, turning good welds into great ones.

Conclusion

Now, you’ve got the full scoop on the 7018 1/8 welding rod amperage chart, from basic settings to tweaking for real jobs. Whether you’re a weekend warrior or full-time fabricator, nailing that 90-160 amp range means stronger, safer welds that last. You’ll avoid common pitfalls like porosity or undercut, saving time and materials.

Always run a test bead on similar scrap before the real deal – it reveals how your specific setup behaves, preventing headaches down the line. Get out there, fire up that welder, and build something solid.

FAQs

What amperage should I use for vertical welding with 1/8 7018 rods?

For vertical ups, stick to 110-130 amps to control the puddle and prevent slag runs. I’ve found 120 hits the mark on most mild steel, letting you weave without dripping.

How do I know if my amperage is too high with 7018 rods?

If the rod overheats, the arc spits, or you get excessive spatter and undercut, dial it back. On a job site fix, I spotted this when beads flattened too much – dropped 15 amps and it smoothed out.

Can I use 7018 rods on rusty metal?

Yes, but grind off heavy rust first. Higher amps like 130-150 help burn through light scale, but clean metal always gives better results. Skipped cleaning once and got porous welds – lesson learned.

What’s the best way to store 7018 welding rods?

Keep them in a rod oven at 250°F to stay dry. If not, rebake at 300°F for an hour. Damp rods crack welds; I’ve salvaged batches this way after humid storage.

How does amperage affect weld penetration with 1/8 7018?

Higher amps increase penetration, ideal for thick joints, but risk burn-through on thin stuff. Start mid-range at 125 and adjust based on the puddle – deeper for roots, lower for fills.