Dialing in the right stick welding amperage is one of those things that can make or break a weld. I’ve burned through rods way too fast — or fought a stubborn arc that just wouldn’t stay lit — simply because the amps were a little off.

Every electrode behaves differently, and factors like rod diameter, metal thickness, and joint prep all play a role in where your amperage should land. Whether you’re running 6011 on rusty steel, 7018 on structural work, or switching between stick, MIG, and TIG on the same job, having a reliable Stick Welding Amperage Chart saves a ton of trial and error.

The right settings mean smoother arc control, better penetration, stronger welds, and less spatter — which matters for safety, structural integrity, and efficiency in the real world. I’m about to break down the amperage ranges I trust in the shop and how to fine-tune them for your exact setup.

The Fundamentals of Stick Welding Amperage

Stick welding, or shielded metal arc welding, uses an electrode coated in flux to create an arc that melts both the rod and the base metal, forming a solid joint as it cools.

Amperage is the current flowing through that arc, and it’s what controls the heat. Too low, and your weld bead looks like a string of pearls with poor fusion. Too high, and you’re digging holes in the metal.

In my early days, I was welding farm equipment repairs, and I learned quick that amperage isn’t one-size-fits-all. It depends on the electrode type, size, the metal you’re working with, and even the position you’re welding in.

A good stick welding amperage chart breaks it down by these factors, giving you ranges to start from. For instance, on mild steel, which is what most of us deal with in the US, you’ll adjust based on thickness to avoid distortion.

Think of it like tuning an engine—you want just enough power for the job without redlining it.

Practical tip: Always start at the lower end of the range and dial up as needed. That way, you test on scrap first, saving your good material.

Common Electrode Types and Their Amperage Settings

Electrodes are the heart of stick welding, and each type has its sweet spot for amperage. The AWS classification system labels them, like E6010 or E7018, telling you about tensile strength, position, and coating. I’ll focus on the popular ones for mild steel, since that’s 90% of what DIYers and pros handle.

E6010 Electrodes: Deep Penetration for Dirty Jobs

E6010 rods are my go-to for outdoor work or rusty metal because their cellulose coating gives a forceful arc that digs deep. They’re all-position but shine in vertical down or overhead where control matters.

For amperage, a 3/32-inch E6010 runs best at 40-85 amps, perfect for thin to medium stock up to 3/16 inch. Bump to 1/8-inch diameter, and you’re looking at 75-125 amps for 1/8 to 1/4-inch metal.

I once fixed a cracked plow frame on a farm using 1/8-inch at 100 amps—started low to avoid blowing through the thin sections, then cranked it for the thicker parts. Use DCEP polarity for max penetration; AC works but with more spatter.

Tip: If the arc wanders, up the amps slightly. Common mistake? Running too hot on clean metal, causing undercut—dial back and whip the rod for better control.

E6011 Electrodes: Versatile for AC Machines

Similar to 6010 but with potassium for smoother AC operation, E6011 is great for hobbyists with older buzz box welders. It’s forgiving on contaminated surfaces and good for all positions.

Amperage chart wise, 3/32-inch needs 40-85 amps, handling up to 3/16-inch thick. For 1/8-inch, 75-125 amps covers 1/8 to 1/4-inch. On 5/32-inch, go 110-160 amps for heavier stuff. In my shop, I use 1/8-inch at around 90 amps for general repairs—it’s stable and leaves a flat bead.

Polarity: DCEP or AC. Pro tip: For vertical up, drop amps by 10% to keep the puddle from sagging. Mistake to avoid: Sticking the rod by starting too cold; preheat if the metal’s chilly.

E6013 Electrodes: Easy Starts for Beginners

E6013 is rutile-coated for a soft arc, making it ideal for thin sheets or cosmetic welds. It’s not as penetrating, so save it for clean, flat work.

Settings: 3/32-inch at 50-90 amps for up to 1/8-inch metal. 1/8-inch at 80-130 amps for 1/8 to 3/16-inch. I taught a student once who burned through aluminum-coated steel because he ran 1/8-inch at 120 amps—lesson learned: Start at 90 and watch the puddle.

Use AC or DCEP/DCEN. Tip: Great for tacking; low amps reduce distortion. Common fix: If slag traps, increase travel speed.

E7018 Electrodes: Low-Hydrogen for Critical Welds

E7018 is the pro’s choice for high-strength, crack-resistant welds on structural steel. Low-hydrogen coating means preheating and dry storage to avoid porosity.

Amperage: 3/32-inch 70-110 amps for thin to medium. 1/8-inch 90-165 amps for 1/8-inch up. 5/32-inch 130-220 amps for thick plates. On a bridge repair job, I ran 1/8-inch at 130 amps—perfect fusion without excess heat.

DCEP mostly; AC possible with specific variants. Tip: Drag technique for flat beads. Mistake: Damp rods cause hydrogen cracking—bake them if needed.

Other Electrodes: Quick Hits on 7024 and More

7024 is iron powder-coated for high deposition in flat/horizontal positions. Amps: 1/8-inch 140-180. Great for filling large joints fast.

For stainless or cast iron, like 308L, adjust lower—say 50-100 amps for 3/32-inch—to prevent cracking.

Always check the box for exact ranges, as brands vary slightly.

Amperage Based on Metal Thickness and Rod Size

Metal thickness drives everything. Thin stuff needs low amps to avoid holes; thick requires high for penetration.

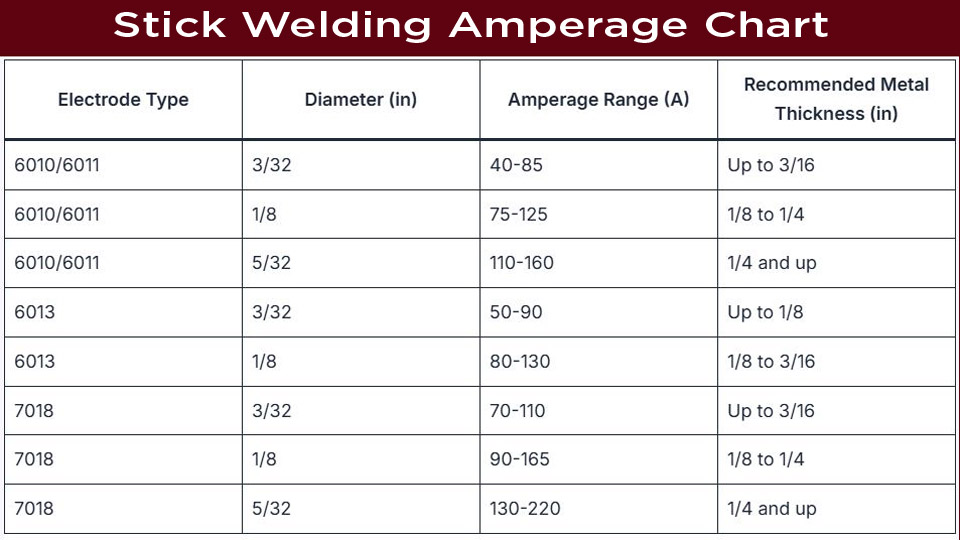

Here’s a handy chart I put together from years of trial and error:

| Electrode Type | Diameter (in) | Amperage Range (A) | Recommended Metal Thickness (in) |

|---|---|---|---|

| 6010/6011 | 3/32 | 40-85 | Up to 3/16 |

| 6010/6011 | 1/8 | 75-125 | 1/8 to 1/4 |

| 6010/6011 | 5/32 | 110-160 | 1/4 and up |

| 6013 | 3/32 | 50-90 | Up to 1/8 |

| 6013 | 1/8 | 80-130 | 1/8 to 3/16 |

| 7018 | 3/32 | 70-110 | Up to 3/16 |

| 7018 | 1/8 | 90-165 | 1/8 to 1/4 |

| 7018 | 5/32 | 130-220 | 1/4 and up |

Rule of thumb: 1 amp per 0.001 inch of rod diameter as a start. For 1/8-inch (0.125), that’s 125 amps mid-range.

Prep work: Clean metal with a grinder; bevel edges on thick joints for better fusion. Tip: For 1/4-inch steel, use 5/32-inch rod at 140 amps—multi-pass if needed.

Adjusting Amperage for Weld Position and Joint Type

Position changes everything. Flat is forgiving; overhead demands control.

For vertical up, drop amps 10-15% to manage gravity—say, 100 amps instead of 115 for 1/8-inch 6011. Vertical down? You can push higher for speed.

Overhead: Lower amps, shorter arc to avoid drips.

Joint types: Butt joints need full penetration, so mid to high range. Fillets? Lower to prevent undercut.

In a fab shop, I welded overhead brackets at reduced amps—saved me from molten metal showers. Mistake: Ignoring position leads to sagging beads; practice on scrap.

Polarity matters too: DCEP for deep dig, DCEN for faster deposition on thin stuff.

Step-by-Step Guide to Setting Up Your Stick Welder

Ready to get hands-on? Here’s how I do it every time.

- Select your electrode based on metal and job—6011 for versatility.

- Check thickness and choose diameter—smaller for thin.

- Consult the chart for range—start mid.

- Set polarity—DCEP for most.

- Strike the arc on scrap, adjust amps: If rod sticks, up it; if spatter’s wild, down.

- Prep joint: Clean, clamp, bevel if over 1/4-inch.

- Weld: Maintain 1/8-inch arc length, steady travel.

- Inspect: Chip slag, check for cracks.

I walked a buddy through this on his first gate repair—started at 80 amps on 1/8-inch rod, ended at 95 for perfect beads.

Common Mistakes with Amperage and How to Fix Them

Too low amps: Rod freezes, bead’s convex with poor tie-in. Fix: Increase 10 amps, strike hotter.

Too high: Burn-through, wide beads, warping. Drop amps, use weaving.

Ignoring material: Cold metal sucks heat—preheat or up amps.

Anecdote: I warped a trailer frame once with high amps on thin tube—now I always test.

Safety: High amps mean more UV—wear proper PPE, ventilated space.

Equipment Recommendations for Optimal Amperage Control

Your welder matters. For hobbyists, a 140-amp inverter like those from US brands handles up to 1/8-inch rods fine.

Pros: Go 225-amp for thicker work. Engine-driven for field jobs.

Tip: Digital displays help fine-tune. Match duty cycle to amps—don’t overheat.

In my workshop, I swear by a multi-process unit for switching processes seamlessly.

Safety and Best Practices in Stick Welding

Amperage ties to safety—high settings increase risks.

Always ground properly, wear flame-resistant gear, helmet with right shade.

Ventilate for fumes; low-hydrogen rods reduce hazards.

US codes like OSHA stress this—inspect cables, avoid wet areas.

Personal story: A spark from high-amp spatter burned my glove once—now I double-check everything.

Pros and Cons of Different Amperage Settings

Low amps: Pros—less distortion, easier control on thin; cons—slow, poor penetration.

High: Pros—fast, deep; cons—warping, spatter.

Balance is key for efficiency.

Comparison table for quick ref:

| Setting | Pros | Cons | Best For |

|---|---|---|---|

| Low | Minimal heat input, precise | Slow deposition, sticking | Thin metals, overhead |

| Medium | Good fusion, stable arc | Average speed | General repairs |

| High | Deep penetration, fast | Warping, burn-through | Thick plates, flat positions |

Advanced Tips for Fine-Tuning Amperage

Once basics are down, experiment. For alloy steels, lower amps to avoid brittleness.

Multi-pass welds: Lower for root, higher for fill.

Weather: Windy outdoors? Up amps slightly for stability.

I refined this on pipeline jobs—small tweaks make big differences.

Conclusion

You’ve now got the guide to tackle any stick welding job with confidence using that amperage chart. From picking the right electrode to adjusting for position, you’re set for safer, stronger welds that save you time and money. Remember, it’s all about practice—grab some scrap and dial in those settings.

Always keep a laminated chart in your toolbox; it’s saved my hide more times than I can count. Now get out there and lay some beads!

FAQ

What amperage should I use for a 1/8-inch 7018 rod on mild steel?

For 1/8-inch 7018 on mild steel, aim for 90-165 amps, starting around 120 for 1/8 to 1/4-inch thick. Adjust based on position—lower for vertical to control the puddle.

How do I know if my amperage is too high in stick welding?

Signs include excessive spatter, a wide and flat bead, burn-through on thin metal, or the rod glowing red. Drop the amps by 10-20 and test again for a smoother arc.

Can I use the same amperage settings for AC and DC in stick welding?

Not exactly—AC often needs 10% higher amps than DC for stability due to the waveform. Check your electrode; some like 6011 handle AC well, but always verify on scrap.

What’s the best electrode for beginners learning amperage control?

Start with E6013—its forgiving arc makes amperage tweaks easier. Use 3/32-inch at 50-90 amps on thin sheet to build confidence without major defects.

How does metal thickness affect stick welding amperage?

Thicker metal requires higher amps for penetration—e.g., under 1/8-inch, stay below 100 amps to avoid holes; over 1/4-inch, push 130+ with larger rods for solid fusion. Always match rod size accordingly.