Understanding standard welding symbols is one of those skills that can save you from costly mistakes on the shop floor. I’ve been handed plenty of drawings that looked simple at first glance, only to realize the weld callouts were telling a very different story than what I initially planned to run.

Between fillet weld symbols, groove symbols, sizes, lengths, and notes for MIG, TIG, or stick welding, it’s easy to get confused if you don’t read them the right way. A lot of welders wonder what side of the joint to weld, how big the weld needs to be, or whether a specific joint prep is required — and the answers are usually right there in the symbols.

Getting this right matters for weld quality, structural strength, and passing inspections without rework. In this guide, I’ll break down standard welding symbols in plain language, so you can read prints with confidence and weld exactly what the job calls for.

What Are Standard Welding Symbols Anyway?

Think of standard welding symbols as the blueprint’s way of yelling instructions without a novel’s worth of text. They’re graphical shortcuts that tell you exactly what weld to lay down, where, and how. Born from standards that folks in the industry follow—like those AWS guidelines we all reference—they pack in details on joint type, size, and finish into a compact form.

In my experience, these symbols bridge the gap between the engineer dreaming up the design and the welder with the torch in hand. Without them, you’d be guessing on everything from fillet size to groove prep, leading to mismatched materials or weak spots.

I’ve seen hobbyists in home garages skip them and end up with warped frames because they didn’t account for penetration depth. Pros know better; they ensure every bead contributes to the structure’s longevity.

Why bother? Safety tops the list—a symbol calling for full penetration might prevent a catastrophic failure on a load-bearing beam.

Then there’s efficiency: right symbols mean less grinding or filler waste, keeping costs down on big jobs like pipeline repairs. In fabrication, they’re your roadmap for reliable welds, whether you’re TIG-ing aluminum or MIG-ing mild steel.

The Basic Building Blocks of a Welding Symbol

Every symbol starts with a few core pieces, like the frame of a good weld joint. First up is the arrow—it points straight to where the action happens, the joint itself. It’s like me jabbing a finger at a blueprint and saying, “Weld right here.” The arrow side is crucial; whatever’s below the reference line applies to the side the arrow’s pointing at.

Then there’s the reference line, that straight horizontal bar everything hangs off. It’s the backbone, holding details like weld type and dimensions. Info below it is for the arrow side, above for the other side. I’ve botched this early on, welding on the wrong face and having to grind it all out—lesson learned: always double-check the line’s orientation.

The tail comes last, tacked on the end opposite the arrow. It’s optional, but when it’s there, it spills extras like the welding process or filler spec. Think “MIG with ER70S-6” scribbled in. In shop practice, we use it for quick notes on electrodes or even non-destructive testing requirements. Skip reading the tail, and you might grab the wrong rod, leading to porosity or cracks.

Put them together, and you’ve got a symbol that’s simple yet loaded. On a T-joint blueprint, an arrow pointing to the stem with a triangle below the line means fillet on that side. Add numbers, and it specifies size. I’ve trained new guys by sketching these on scrap metal—hands-on beats theory every time.

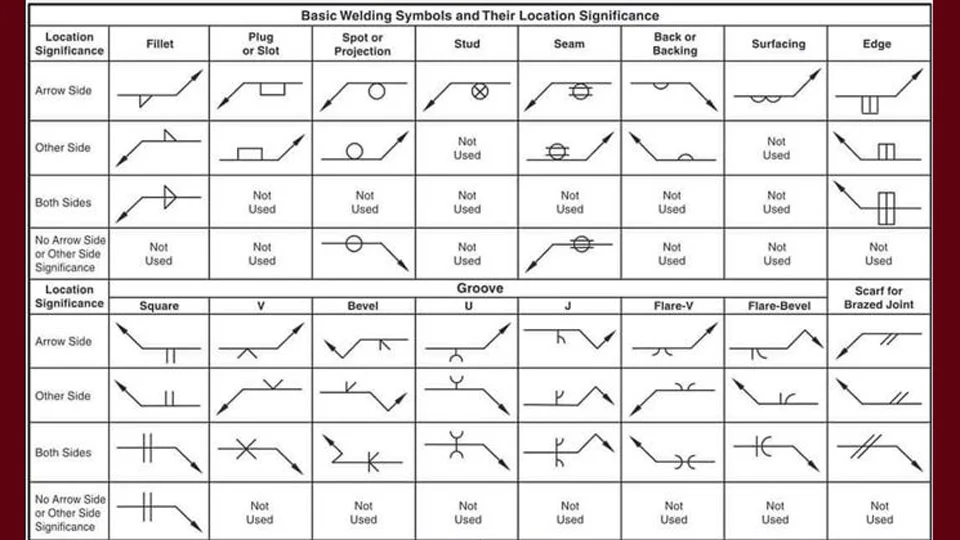

Common Weld Types and Their Symbols

Weld types are where the rubber meets the road, or rather, where the arc meets the metal. Each has its symbol, shaped like a cross-section of the weld itself. Let’s break them down, starting with the ones you’ll see daily in any US fab shop.

Fillet Weld Symbols

The fillet’s your go-to for corners, laps, and T-joints—think welding a bracket to a frame. Symbol? A right triangle plopped on the reference line. If it’s below, weld on the arrow side; above, the other.

Size matters here; a number left of the triangle, like 1/4, means leg length in inches. Uneven legs? Two numbers separated by an X, oriented to match the joint. I’ve used these on everything from trailer hitches to machinery guards.

Pro tip: For intermittent fillets—stitch welds—add length and pitch to the right, like 2-4 for 2-inch beads every 4 inches. Saves filler on long runs without sacrificing strength.

When to use? When you need quick, strong bonds without full penetration. Why? It’s forgiving on fit-up; a little gap won’t kill it. But watch material thickness—too thin, and you’ll burn through. Common mistake: Over-welding for “safety,” which warps the piece. Fix? Stick to the symbol’s spec and preheat if needed.

In my shop days, I’d set my MIG at 18-20 volts for 1/4-inch mild steel fillets, wire speed around 300 IPM. Joint prep’s simple: Clean edges with a grinder, tack first. Compatible fillers? ER70S-6 for carbon steel. If no machine’s handy, I’ve improvised with stick welding, adjusting amps down for control.

Groove Weld Symbols

Grooves are for beefy joints needing deep fusion, like butt welds on thick plate. The symbol mirrors the groove shape—V for V-groove, U for U, and so on. Placed on the reference line, with details like angle (A) or root opening (R) nearby.

Take a single V-groove: Arrow points to the edge, V symbol below the line, maybe 60° angle noted. Depth of prep (S) and penetration (E) get numbers too. I’ve laid these on pipeline sections; full pen ensures no leaks under pressure.

Variants abound: Bevel for one-sided access, J for less filler, square for thin stuff. Double grooves? Symbols on both sides of the line. When? For high-stress apps like structural beams. Why? Better strength than fillets in tension.

Mistakes? Poor bevel angle leads to incomplete fusion. Fix: Use a protractor on prep. Settings: For TIG on stainless, 100-150 amps, argon shield. Prep: Flame-cut edges, grind smooth. Filler: Match base, like 308L for 304 stainless. No grinder? File it—old-school but works.

Here’s a quick comparison table for groove types:

| Groove Type | Symbol Shape | Best For | Pros | Cons |

|---|---|---|---|---|

| Square | Straight lines | Thin plates | Easy prep | Limited penetration |

| V | V shape | General butt joints | Good fusion | More filler needed |

| Bevel | Slanted line | One-side access | Less material removal | Asymmetrical |

| U | U shape | Thick sections | Reduced distortion | Complex machining |

| J | J shape | Similar to U | Saves filler | Harder to prep |

This table’s saved me time picking the right one for jobs.

Plug and Slot Weld Symbols

For overlapping plates with holes, plug’s your symbol—a rectangle on the line. Plug for round holes, slot for elongated. Number left for size (diameter or width), right for pitch if multiple.

I’ve plugged holes in truck beds to attach reinforcements. When? To join without edge access. Why? Flush finish, strong shear resistance.

Common error: Underfilling, causing weak spots. Fix: Weld in layers. Settings: Stick at 120 amps for 1/8 rod. Prep: Drill clean, deburr. Filler: E7018 for low-hydrogen needs. Alternative: If no drill, punch holes—crude but effective in the field.

Spot and Seam Weld Symbols

Spot’s a circle—simple as that. For resistance welding overlapping sheets, like auto panels. Circle straddling the line if both sides matter.

Seam adds parallel lines inside the circle for continuous runs. I’ve seamed fuel tanks; leak-proof is key.

When? Thin metals, high production. Why? Fast, no filler. Mistake: Overheating, warping. Fix: Pulse settings. Equipment: Spot welder at 10-15 kA. No fancy gear? Use MIG spots, but it’s messier.

Other Essential Weld Symbols

Surfacing: Half-circles for building up worn parts, like plow blades. Number for thickness.

Backing: Half-circle for support strips. R means remove after.

Stud: Pitched circle for fastening studs, common in construction.

Edge: Two rectangles for flanging sheet edges.

Each has its niche—I’ve backed grooves on heavy plate to catch molten metal, preventing burn-through.

Supplementary Symbols That Add the Details

These extras tweak the main symbol, like fine-tuning your welder’s voltage.

Field weld: A flag at the arrow-line junction. Means “Do this on-site.” I’ve flagged pipeline joints—pack your portable rig.

All-around: Circle there instead. Weld full circumference, like around a pipe flange. Skip it, and leaks happen.

Melt-thru: Filled half-circle for root reinforcement visible opposite side. Height noted. Critical for tanks.

Consumable insert: Square for root pass aids. Class in tail.

Backing/spacer: Rectangle for gap control or heat sink.

Contour: Line above symbol—straight, convex, concave. Affects fatigue resistance.

Finishing: Letters like G for grind, C for chip. Post-weld cleanup.

I’ve ground contours smooth on visible rails—looks pro, reduces stress risers.

How to Read a Welding Symbol Step by Step

Blueprint in hand—let’s walk through it like I’m over your shoulder.

Step 1: Spot the arrow. It points to the joint. Note arrow side vs. other.

Step 2: Check the reference line. Weld symbol on it tells type—triangle fillet, V groove.

Step 3: Read positions. Below line: arrow side. Above: other. Both? Dual welds.

Step 4: Decode numbers. Left: Size/depth. Right: Length/pitch. Parentheses: Penetration.

Step 5: Tail check. Process like GMAW (MIG), filler spec.

Step 6: Supplementals. Flag? Field. Circle? All-around.

Example: Arrow to T-joint, triangle below line, 3/8 left, 4-8 right. Means 3/8-inch fillet on arrow side, 4-inch stitches every 8 inches.

Practice on scrap—I’ve sketched dozens before trusting myself on paying jobs.

Multi-lines? Sequence from arrow out: First pass closest.

Common pitfall: Confusing sides. Mark the piece with chalk.

Real-World Applications in the Shop and Field

In fabrication, symbols dictate everything. On a custom gate, fillet symbols guide quick laps. For repairs, surfacing rebuilds shafts.

Safety: Symbols flag backing for penetration, avoiding undercuts that crack.

Material insights: Tail might spec 5356 aluminum wire for 6061 base—mismatch causes corrosion.

Cost: Intermittent over continuous saves wire. I’ve cut bills 30% that way.

Job-site reliability: Field symbols prep you for wind or rain—bring covers.

Hobbyists: Use on bike frames for strength without bulk.

Students: Start with fillets on mild steel, 140 amps MIG.

Pros: Layer grooves on thick alloy, preheat to 300°F.

Common Mistakes and How to Dodge Them

Biggest blunder: Ignoring the tail. Grabbed wrong rod once, porosity everywhere. Fix: Read full symbol first.

Misreading sides: Welded other side, had to flip heavy assembly. Solution: Visualize with a mock-up.

Overlooking dimensions: Too big fillet warps. Stick to specs, measure post-weld.

Poor prep: Dirty joints from skipped grinding. Always clean to bright metal.

Machine settings off: For symbols calling deep pen, crank amps but watch heat input.

In tight spots, no room for ideal? Adapt—use stick over MIG for access.

I’ve learned these the hard way, grinding out mistakes at midnight.

Advanced Tips for Tricky Symbols

For CJP (complete joint penetration), look for no depth numbers or melt-thru. Backgouge if needed.

Intermittent chains: Offset symbols for staggered.

Contours with finish: Convex G means grind smooth—reduces corrosion pockets.

In alloys, symbols guide preheat; ignore, cracks form.

Portable alternatives: Battery welders for field flags.

Why Mastering These Makes You a Better Welder

You’ve now got the lowdown on standard welding symbols—from basics to the nitty-gritty of grooves and fillets. You’re equipped to read blueprints like a seasoned pro, spotting details that ensure strong, safe welds. No more guessing on joint prep or filler choice; you’ll save time, cut costs, and avoid those rework headaches that plague greenhorns.

Why better prepared? Because in the real world, whether DIY-ing a workbench or fabbing industrial gear, these symbols are your safety net for integrity and efficiency. You’ll choose the right process—MIG for speed, TIG for precision—and match materials flawlessly.

Always carry a laminated symbol chart in your toolbox. It’s bailed me out on remote jobs when blueprints got smudged, letting me confirm a groove angle without second-guessing.

What Does the Arrow in a Welding Symbol Really Mean?

That arrow’s your pointer to the exact joint location. It defines the “arrow side” for weld placement—below the reference line means weld there. I’ve used it to avoid welding the wrong face on assemblies, saving flips and frustration.

How Do I Know If a Weld Needs to Be All-Around?

Look for a circle where the arrow meets the reference line. It screams “weld full circle.” Common on pipes or tanks—I’ve circled flanges countless times for leak-proof seals. No circle? Just the arrow-pointed spot.

What’s the Difference Between Arrow Side and Other Side?

Arrow side is where the arrow points; details below the line apply there. Other side’s the opposite, with info above the line. Mess this up, and your weld’s misplaced. Pro move: Sketch the joint 3D to visualize.

Why Is There a Tail on Some Symbols But Not Others?

The tail’s for extras like process (e.g., TIG) or filler rod type. Omitted on simple jobs to keep clean. In my experience, tails pop up on critical welds needing specific electrodes to match base metal and avoid cracks.

How Can I Avoid Common Mistakes When Reading Groove Symbols?

Double-check angles and depths—wrong prep leads to poor fusion. Measure bevels with a gauge, and backgouge for full pen if called for. I’ve fixed many by grinding and re-welding, but prevention’s key: Follow the numbers religiously.