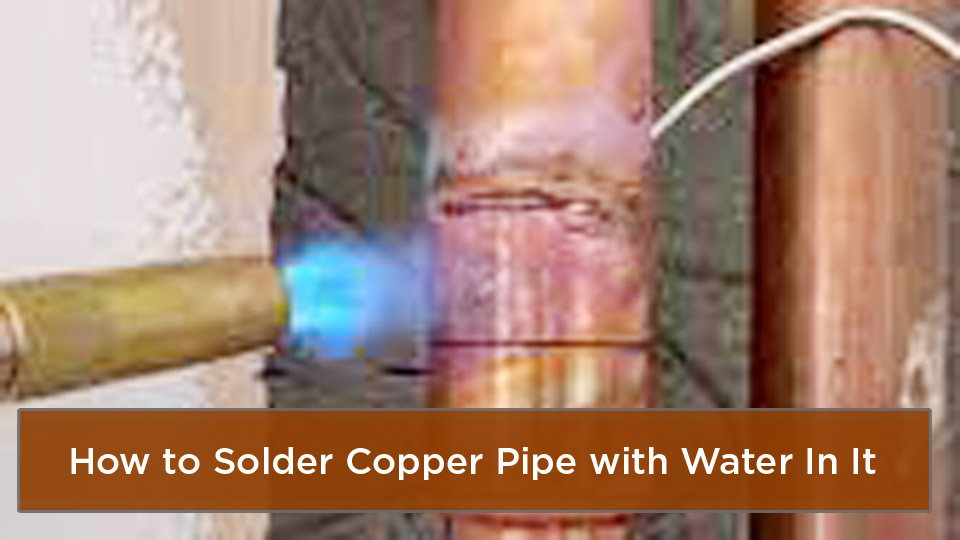

Trying to solder a copper pipe with water in it is one of those jobs that’ll test your patience — and your torch control. I’ve been there more times than I’d like to admit, standing over a fitting that just won’t take solder because a little water keeps sneaking back into the joint.

The heat fights against the moisture, the flux burns off too soon, and the solder just blobs instead of flowing. It’s a common headache for plumbers, welders, and DIYers alike.

Whether you’re used to MIG or TIG welding, or just doing some copper joint prep with a torch and filler, moisture is the enemy of good solder flow and proper bonding. Learning how to deal with it the right way saves time, frustration, and callbacks.

In this guide, I’ll show you some tried-and-true tricks to solder copper pipe even when water’s working against you — and get a clean, leak-free joint every time.

Image by mm_plumber

Why Water in the Line Turns a Simple Sweat Job into a Nightmare

Water and molten solder don’t mix—period. When even a drop hits that 400-degree copper, it flashes to steam and blows your joint apart. I’ve watched new guys chase their tail for hours heating the same fitting because they didn’t believe a thimble of water could ruin everything.

In the real world, this happens on every repipe where the main valve won’t fully close, or when you’re adding a branch to a live system in an occupied house.

Get this right, and you’ll save hundreds on callbacks. Get it wrong, and you’re explaining to an angry homeowner why their hardwood is now a swimming pool.

The Tools That Live in My Truck for Every Wet Soldering Emergency

Before we dive into the tricks, here’s exactly what I keep ready:

- Bernzomatic TS8000 torch with MAP-Pro gas (hotter than propane, lights faster)

- Oatey No. 95 lead-free solder (the tinning flux built in is clutch)

- Oatey No. 5 paste flux for extra insurance

- White Wonder bread (yes, the cheap stuff—zero crusts)

- Milwaukee M12 shop vac with the skinny nozzle

- 25-foot coil of 1/4-inch clear vinyl tubing for siphoning

- Expanding rubber freeze plugs (the ones plumbers swear by)

- A roll of paper towels and a spray bottle of water for cooling

Keep these in a dedicated “wet joint” bucket. When the call comes in, you’re not scrambling.

The Bread Trick: My Most-Used Hack Since 2008

I know it sounds like an old-timer’s tale, but I’ve soldered hundreds of joints with bread holding back a trickle. Grab two slices of plain white bread—nothing fancy, no seeds, no whole wheat nonsense. Strip the crusts, roll it into a tight ball about the size of a golf ball, and jam it 6-8 inches upstream of your fitting with a dowel or pencil.

The bread swells instantly and blocks the flow for 3-5 minutes—plenty of time to clean, flux, and sweat the joint. When you turn the water back on, the pressure dissolves the bread into tiny pieces that flush right out. I’ve never once had it clog an aerator when I remembered to pull the screens first.

Pro move: If the drip is heavy, stuff TWO bread balls staggered 4 inches apart. The first one takes the initial hit while the second seals tight.

Shop Vac Method: When Bread Won’t Cut It

Sometimes you’re dealing with more than a drip—maybe a steady stream from a crappy gate valve. That’s when I break out the shop vac. Shove the nozzle right over the open pipe end and seal it with a rag. Turn it on high, and watch that water disappear like magic.

The vacuum pulls the water column away from your joint for 30-45 seconds. Keep the vac running while your buddy fluxes and slides the fitting on. I’ve done entire bathroom rough-ins this way when the homeowner refused to shut off the main for “just five minutes.”

Compressed Air Blast: The Fastest Way to Clear a Stubborn Line

Got an air compressor? You’re golden. Hook up a blow gun with a rubber tip, stick it in the pipe, and give it a 2-second burst at 90 psi. The air pushes the water downstream instantly. I keep a cheap Campbell Hausfeld 3-gallon pancake compressor in the van just for this.

Word of caution: Wear safety glasses. That water shoots out like a fire hose, and I’ve taken a face full more than once.

Expanding Freeze Plugs: The Bulletproof Option for Big Jobs

When I’m on a commercial repipe with 1-inch lines running water, I grab my Arctic Cove freeze kit. These rubber plugs expand with a wrench and seal like nobody’s business. Slide it in 12 inches past your joint, tighten, and forget about water for an hour.

Yeah, they’re $40 each, but they’ve paid for themselves tenfold on condo buildings where shutting water means notifying 40 units.

Step-by-Step: Sweating That Joint When Everything’s Against You

Let’s do this together like you’re my helper on site:

- Cut your pipe square with a proper tubing cutter—never a hacksaw unless you’re desperate.

- Ream the inside edge smooth. Burrs kill solder flow.

- Sand the pipe end and fitting socket shiny with 120-grit emery cloth. I spin the pipe while holding the cloth.

- Apply flux generously but not sloppy. I use an acid brush—the $2 ones from Home Depot.

- Choose your water-blocking method (bread for most jobs).

- Assemble the joint while your torch is lighting.

- Heat the fitting, not the pipe. Start opposite the gap where solder goes in.

- When the flux starts bubbling like crazy, touch solder to the edge. It should wick in like a straw.

- Keep the flame moving. Count to 8-Mississippi on 1/2-inch, 12 on 3/4-inch.

- Wipe with a damp rag while hot to clean flux and see your perfect silver ring.

If it doesn’t take, cool it, disassemble, reclean, and try again. Patience wins.

Machine Settings That Make the Difference

Torch on full blast with MAP-Pro gives me 3,600°F—perfect. Propane guys, open the valve 1.5 turns and keep the tip clean. I adjust flame to a 2-inch blue dart with a soft yellow feather. Too bushy and you’ll oxidize everything.

Common Mistakes I’ve Made (So You Don’t Have To)

- Using rye bread once in a pinch—clogged three aerators and cost me a Saturday.

- Heating the solder directly instead of the fitting. Creates balls that don’t seal.

- Forgetting to pull faucet aerators before flushing bread. Learned that the hard way in a $2 million house.

- Soldering downward joints with bread—the weight pushes it out. Always block upstream.

Which Method Should You Use?

| Method | Time to Dry | Cost | Best For | Success Rate in My Experience |

|---|---|---|---|---|

| Bread Ball | 30 seconds | $0.10 | Residential drips, 1/2″-3/4″ | 95% |

| Shop Vac | 2 minutes | $0 | Steady streams, any size | 98% |

| Compressed Air | 10 seconds | $0 | Quick bursts, open ends | 99% |

| Freeze Plugs | 5 minutes | $40 | Commercial, large diameter | 100% |

| Siphoning Tube | 10 minutes | $5 | Low spots, gravity drain | 85% |

When to Ditch Soldering Altogether: SharkBite and ProPress Save Marriages

Real talk—sometimes the water wins. I’ve got a Ridgid RP 351 press tool that crimps ProPress fittings in 7 seconds with water pouring out. Zero flame, zero drama. SharkBite push-fits are my emergency go-to when I’m solo and the bread keeps dissolving.

They’re code-approved nationwide now, and I’ve never had one leak in 10 years. Yeah, they’re pricier, but so is a flooded basement.

Safety Rules I Never Break

- Leather gloves always—molten solder burns are no joke.

- Fire extinguisher within arm’s reach.

- Ventilate crawl spaces. Flux fumes will drop you.

- Safety glasses. Steam explosions shoot solder like bullets.

- Never leave a hot torch unattended. I’ve seen vans burn because someone set it on a seat.

Real Job Stories That Taught Me These Tricks

That time in Chicago when the 1920s gate valve stripped and we had a 1/4-inch stream—bread wouldn’t hold. My partner grabbed the shop vac while I prepped fittings. We soldered 12 joints in 40 minutes and the super bought us steaks.

Or the Florida condo where the HOA wouldn’t allow water shutoff during season. Freeze plugs let us repipe 18 units without a single complaint.

Testing Your Work Like a Pro

Turn water on SLOW. If you hear hissing, shut it down immediately. Pressurize to 80 psi and walk away for 10 minutes. Come back with paper towel—if it’s dry, you’re golden. I always mark joints with Sharpie so I know what I touched.

Conclusion

The exact playbook I’ve used to solder thousands of wet copper joints without a single flood. Master these tricks, and you’ll walk onto any job site with confidence. Next time someone says “you can’t solder with water in the line,” just smile and reach for the bread.

Keep a spare slice of bread in your wallet. Sounds crazy, but when you’re 40 feet up on a ladder with a dripping pipe, you’ll thank me.

FAQs

Can you solder copper pipe that’s completely full of water?

Not a chance without draining first. These tricks work for drips and trickles, not flowing water.

Will the bread really dissolve completely?

Yes, with plain white bread. I’ve flushed miles of pipe—never found a chunk.

What’s the best solder for potable water lines?

Oatey Safe-Flo silver solder or any ASTM B813 lead-free. Stay legal and safe.

How long do I need to wait before turning water back on?

30 seconds after wiping. The joint cools fast enough.

Can I use these methods on PEX or CPVC?

Nope—these are copper-only tricks. Different animals entirely.