Dialing in the right settings for flux core MIG welding was something that used to slow me down on a lot of jobs. I’d switch from 1/8″ plate to thin-gauge steel, tweak the voltage and wire feed speed, and still end up fighting spatter, poor penetration, or a bead that just didn’t look right.

That’s when I realized how important a solid flux core MIG welding settings chart really is — especially when you’re juggling different metal thicknesses, joint prep, and trying to maintain good arc control. Compared to MIG or TIG welding, flux core runs hotter and reacts differently depending on wire type, polarity, and even how clean your steel is.

Getting the right settings isn’t just about a pretty bead; it directly affects weld strength, safety, and how efficiently you use your wire and machine. I’m about to break down the exact settings and adjustments that have saved me countless hours — and a lot of frustration — in the shop.

Understanding Flux Core MIG Welding Basics

Flux core MIG welding is basically MIG welding’s rugged cousin—it’s that process where you feed a tubular wire filled with flux through your welding gun, and that flux creates its own shielding gas as it burns, protecting the molten pool from air contaminants.

How it works is simple: you strike an arc between the wire and your workpiece, the heat melts the wire and base metal, and the flux vaporizes to form a gas shield while also adding deoxidizers to clean up impurities.

I remember my first time trying it on a windy job site; no gas bottle to lug around, and it held up way better than standard MIG.

You’ll want to use flux core when you’re working outdoors where wind blows away shielding gas, or on dirty, rusty steel that would require hours of grinding otherwise. Why? Because it’s forgiving on prep work and penetrates deeper on thicker materials.

Practical know-how: always check your machine’s duty cycle—I’ve overheated a few budget welders by pushing them too hard on long runs. Semantic tip here—think about your arc stability; a steady buzz means good settings, while popping sounds scream for adjustments.

In my experience, starting with self-shielded flux core (no external gas) is ideal for beginners or hobbyists, as it simplifies setup. But if you’re in a controlled shop, gas-shielded flux core can give cleaner beads with less smoke.

Common mistake: forgetting to switch polarity to DCEN (direct current electrode negative) for self-shielded wires—I’ve done it, and it led to a globbed-up mess that took forever to clean.

Flux Core vs Solid Wire MIG

Flux core MIG edges out solid wire when you need portability and don’t want to fuss with gas tanks—perfect for field repairs on farms or construction sites across the US.

Solid wire MIG, on the other hand, uses external shielding gas like argon-CO2 mixes for smoother, cleaner welds indoors on clean metal.

How flux core works differently: the flux inside the wire handles the shielding, making it hotter and better for penetration on thicker stock.

Use flux core for outdoor jobs, rusty materials, or when you want higher deposition rates to fill gaps quickly. Solid wire shines for thin sheets or cosmetic work where spatter matters less.

Pros of flux core: no gas needed, deeper penetration, works on dirty surfaces. Cons: more spatter and smoke, which can be a hassle in tight spaces.

I’ve switched to flux core for trailer repairs because it saves time on prep, but I stick with solid wire for auto body work to avoid post-weld grinding.

Tip: If you’re a fabrication hobbyist, test both on scrap—flux core might surprise you with its strength on mild steel joints.

Common fix for mistakes: if your flux core beads look ropey, slow your travel speed to let the pool settle.

Essential Equipment for Flux Core Welding

Your setup starts with a reliable MIG welder rated for flux core—look for models like those from Lincoln or Miller that handle 0.030 to 0.045-inch wires without skipping.

You’ll need flux core wire spools, a drive roll kit with knurled grooves to grip the softer wire, and a good liner in your gun to prevent bird-nesting.

Safety gear is non-negotiable: auto-darkening helmet, leather gloves, respirator for fumes, and fire-resistant jacket.

How it all works together: the welder pushes wire at your set speed, voltage controls the arc heat, and the flux does the rest. For US codes like AWS standards, ensure your machine meets duty cycle requirements for continuous work.

Practical insight: I always keep extra contact tips handy because flux core chews them up faster due to spatter buildup.

Anecdote: On a job welding farm equipment, my cheap gun clogged mid-run—lesson learned, invest in a quality one with good heat dissipation. Tip: For prep, wire brush the joint lightly; over-cleaning isn’t needed with flux core’s deoxidizers.

Polarity Settings for Flux Core

Polarity is key—most self-shielded flux core requires DCEN, where the electrode is negative and work is positive, pushing heat into the base for better penetration. Gas-shielded might use DCEP like solid MIG. Why? DCEN concentrates heat on the wire, melting it faster for deeper welds on thick plates.

Set it by flipping the leads inside your machine—I’ve forgotten once and got a unstable arc that sprayed metal everywhere.

Practical know-how: Check your wire label; E71T-11 types demand DCEN. For students or new trainees, practice on thin stock first to see how polarity affects bead shape—DCEN gives a narrower, deeper profile.

Common mistake: Using DCEP on self-shielded wire leads to poor shielding and porosity. Fix: Double-check before powering up, and listen for that crisp frying bacon sound indicating good arc.

Flux Core Wire Types and Selection

Flux core wires come in self-shielded (like E71T-GS) for no-gas setups and gas-shielded (E71T-1) for cleaner results with CO2 or argon mixes. Self-shielded is my go-to for outdoor work; it’s all-position and handles rust well. Gas-shielded offers less spatter but needs gas.

Select based on material: For mild steel, E71T-11 is versatile. Wire diameter matters—0.030-inch for thin stuff up to 1/8″, 0.035-inch for 3/16″ and up. Why use one over another? Thicker wire deposits more metal faster for heavy fab.

Personal story: I once grabbed the wrong wire for a galvanized repair—ended up with zinc fumes that made me sick. Tip: Match wire to base metal compatibility, and store spools dry to avoid hydrogen cracking.

Pros: High tensile strength, good for vertical welds. Cons: More expensive than solid wire, produces slag to chip off.

Flux Core MIG Welding Settings Chart for Mild Steel

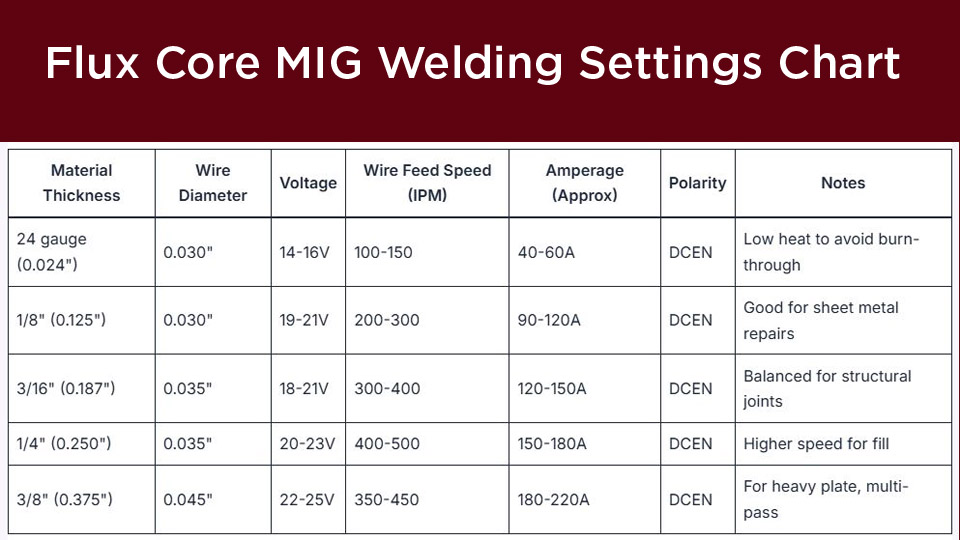

Here’s where the rubber meets the road—a flux core MIG welding settings chart tailored for mild steel, based on what I’ve dialed in over years of trial and error. These are starting points; always test on scrap and adjust for your machine.

| Material Thickness | Wire Diameter | Voltage | Wire Feed Speed (IPM) | Amperage (Approx) | Polarity | Notes |

|---|---|---|---|---|---|---|

| 24 gauge (0.024″) | 0.030″ | 14-16V | 100-150 | 40-60A | DCEN | Low heat to avoid burn-through |

| 1/8″ (0.125″) | 0.030″ | 19-21V | 200-300 | 90-120A | DCEN | Good for sheet metal repairs |

| 3/16″ (0.187″) | 0.035″ | 18-21V | 300-400 | 120-150A | DCEN | Balanced for structural joints |

| 1/4″ (0.250″) | 0.035″ | 20-23V | 400-500 | 150-180A | DCEN | Higher speed for fill |

| 3/8″ (0.375″) | 0.045″ | 22-25V | 350-450 | 180-220A | DCEN | For heavy plate, multi-pass |

These settings assume self-shielded wire on clean-ish steel. For gas-shielded, bump voltage up 1-2V and use 100% CO2 for penetration.

Settings for Different Material Thicknesses

On thin stuff like 24 gauge, keep voltage low around 14-16V to prevent warping—I’ve distorted panels before by going too hot. For 1/8″ steel, 19-21V with 200-300 IPM gives nice flat beads. Thicker 1/4″ needs 20-23V to penetrate without cold laps.

Why adjust? Thinner metal requires less heat to fuse, while thick stock demands more to avoid lack of fusion. Tip: For joint prep on thick plates, bevel edges at 30 degrees for better access.

Common mistake: Same settings for all thicknesses—leads to burn-through on thin, weak welds on thick. Fix: Scale up incrementally and watch the puddle.

Voltage and Wire Feed Speed Explained

Voltage sets arc length and heat—too low, and you get stubbing; too high, excessive spatter. Wire feed speed controls deposition and amps—faster means more metal, hotter weld. They work together: high voltage with low speed for flat beads, opposite for convex.

In practice, start mid-range and tweak. Anecdote: On a fence repair, low speed caused bird-nesting—upped it, problem solved. Semantic: Balance for arc stability, penetration depth.

Common Mistakes in Settings and How to Fix Them

Big one: Ignoring material thickness, leading to poor fusion. Fix: Use the chart, test welds. Another: Wrong polarity—switch to DCEN. Spatter from high voltage? Drop it 1V at a time.

I’ve under-prepped joints, causing porosity—now I always brush scale off. Tip: Listen to the arc; hissing means too much wire, adjust down.

Step-by-Step Guide to Setting Up Your Welder

First, install the flux core wire spool, ensuring proper tension—pinch test it like I do. Second, set polarity to DCEN. Third, choose wire size based on thickness. Fourth, dial voltage and speed per chart.

Fifth, don safety gear. Sixth, test on scrap, adjusting for smooth arc. Seventh, weld with 3/4″ stickout, dragging the gun at 10-15 degrees.

For filler compatibility, match wire strength to base—70ksi for mild steel. In US shops, follow AWS D1.1 for structural.

Troubleshooting Spatter and Porosity

Spatter? Lower voltage or clean tip. Porosity from wind or moisture—move indoors or dry wire. Weak beads: Increase amps via speed.

Story: Porosity ruined a bracket—traced to damp wire, baked it out, fixed.

Safety Considerations in Flux Core Welding

Fumes are intense—use a respirator and ventilation. UV rays burn skin, so cover up. Fire hazards from spatter—keep extinguishers near. I’ve singed gloves ignoring this; now I preach it.

Per US OSHA, maintain good airflow in shops.

Pros and Cons of Flux Core Welding

Pros: Portable, deep penetration, forgiving on dirty metal, cost-effective without gas. Cons: Slag cleanup, more smoke, not for thin precision work.

Great for hobbyists on budgets.

Real-World Applications in US Shops

In auto repair, flux core fixes frames quickly. Construction: Welding rebar or beams outdoors. DIY: Building trailers or gates. I’ve used it on ranch equipment, saving trips to pros.

Tip: For codes, qualify welds if commercial.

Wrapping up

You’ve now got the key takeaways from my years in the trenches: a solid flux core MIG welding settings chart, tips on voltage and speed tweaks, and fixes for common pitfalls that keep your welds strong and safe.

You’re more prepared to tackle that next project with confidence, whether it’s patching a mower deck or fabricating a custom rack—grab your gear, test those settings, and lay down some beads that’ll hold up to anything. Always weld a coupon test piece before the real deal; it’ll save you grief and build your skills faster than anything.

What voltage should I use for flux core welding on 1/8 inch steel?

For 1/8 inch mild steel with 0.030-inch self-shielded flux core wire, start at 19-21 volts. This gives good penetration without burn-through; adjust based on your arc sound for a steady buzz.

How do I choose the right wire feed speed for flux core MIG?

Wire feed speed depends on thickness—200-300 IPM for 1/8 inch works well. Listen for a smooth crackle; too fast causes stubbing, too slow leads to weak fusion. Test on scrap to fine-tune.

What’s the difference between self-shielded and gas-shielded flux core?

Self-shielded needs no external gas, ideal for outdoors and dirty metal with more spatter. Gas-shielded uses CO2 or mixes for cleaner beads indoors but requires a tank setup.

Why is my flux core weld full of spatter?

Excess spatter often comes from high voltage or dirty tips. Drop voltage 1-2V, clean your contact tip regularly, and ensure proper stickout around 3/4 inch for better control.

Can I use flux core for thin sheet metal?

Yes, but carefully—use lower settings like 14-16V on 24 gauge to avoid warping. It’s not as clean as solid wire, so practice on scraps for hobby projects.