When I first got into flux core welding, dialing in the right amperage felt like a guessing game. One pass would be too cold with no penetration, and the next would be so hot I’d be blowing holes through thin steel. That’s when I realized how much easier life gets when you follow a solid flux core welding amperage chart. Matching your wire size, metal thickness, and wire feed speed to the right amperage completely changes how smooth the arc feels — less spatter, better puddle control, and stronger welds that actually tie in.

Whether you’re running .030 or .035 wire, welding outside in the wind, or working on structural repairs, the right settings save time, wire, and frustration. In this guide, I’ll walk you through the amperage ranges that actually work in real shop conditions, plus how to fine-tune your machine so every weld comes out clean and consistent.

What Exactly Is a Flux Core Welding Amperage Chart?

It’s nothing more than a reference table that tells you the sweet-spot amperage (and usually voltage) range for a specific wire diameter, material thickness, and sometimes even the gas/no-gas setup you’re running. Think of it like the torque spec chart in your truck manual — ignore it and you’ll strip threads or leave bolts loose.

Same thing with welding: too cold and you get lack of fusion, too hot and you burn through or get excessive spatter that’ll make you want to throw the stinger in the scrap bin.

Why Getting Amperage Right Matters More Than You Think

I’ve watched guys chase their tail for hours because they were 20 amps too low and couldn’t figure out why the weld wouldn’t tie in on the toes. Wrong heat does four nasty things:

- Weak welds that fail inspection (or worse, fail in service)

- Burn-through on thin sheet that turns your project into Swiss cheese

- Crazy spatter that sticks like concrete and eats your grinding disks

- Wasted wire and gas money because you’re fighting the machine instead of working with it

I’ve lost count of the trailers, gates, and structural jobs I’ve saved just by bumping or dropping 10-15 amps after the first test bead.

How Flux Core Amperage Works: The Simple Science

Flux core wire is basically a tube filled with flux that does the shielding for you (self-shielded) or works with CO2/Argon mix (dual shield). When you pull the trigger, the power supply pushes constant voltage (CV) and the wire feed speed (WFS) directly controls your amperage.

Faster wire feed = more amps = hotter arc. That’s why most charts list wire feed speed in inches per minute (IPM) right next to the amperage range. Learn that relationship and you can dial in almost any machine blindfolded.

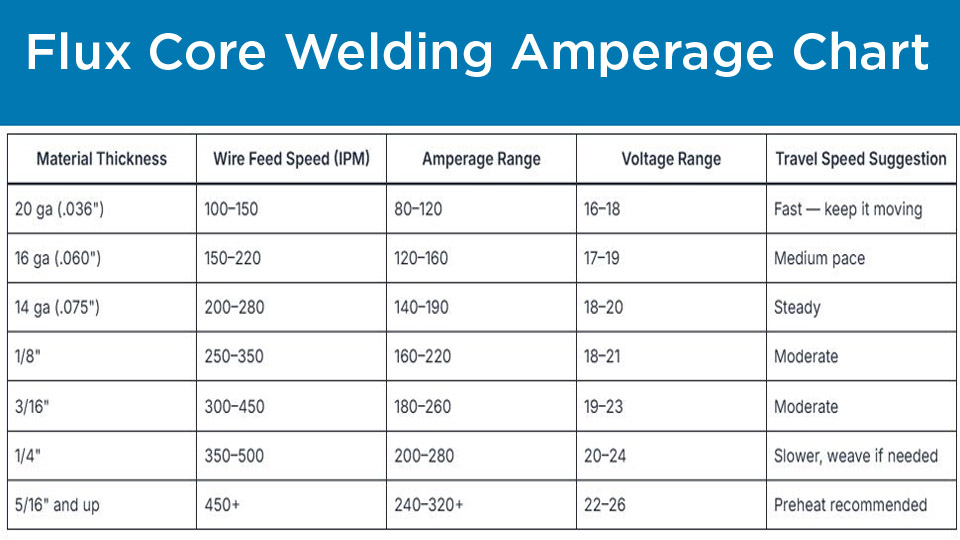

The Only Flux Core Amperage Chart You’ll Ever Need (Self-Shielded .035″ Example)

Here’s the chart I’ve got laminated and zip-tied inside every one of my rig doors. This is for Lincoln NR-211-MP or Hobart Fabshield 21B — the two most common self-shielded .035″ wires in the USA.

| Material Thickness | Wire Feed Speed (IPM) | Amperage Range | Voltage Range | Travel Speed Suggestion |

|---|---|---|---|---|

| 20 ga (.036″) | 100–150 | 80–120 | 16–18 | Fast — keep it moving |

| 16 ga (.060″) | 150–220 | 120–160 | 17–19 | Medium pace |

| 14 ga (.075″) | 200–280 | 140–190 | 18–20 | Steady |

| 1/8″ | 250–350 | 160–220 | 18–21 | Moderate |

| 3/16″ | 300–450 | 180–260 | 19–23 | Moderate |

| 1/4″ | 350–500 | 200–280 | 20–24 | Slower, weave if needed |

| 5/16″ and up | 450+ | 240–320+ | 22–26 | Preheat recommended |

These numbers work on Lincoln, Miller, Hobart, and even the cheap Amazon flux core machines. I’ve run them on everything from a 120V Handler 100 up to a 350P.

Dual Shield Flux Core Amperage Chart (.045″ 75/25 Gas)

When you switch to gas-shielded flux core (E71T-1C or E71T-1M) the numbers climb because the arc is way more efficient.

| Thickness | Wire Feed (IPM) | Amps | Volts | Notes |

|---|---|---|---|---|

| 12 ga | 180–250 | 140–190 | 24–27 | Great for auto body |

| 1/8″ | 220–320 | 180–240 | 25–29 | My go-to for trailer frames |

| 3/16″ | 280–400 | 220–280 | 26–30 | Structural all day long |

| 1/4″ | 350–480 | 250–320 | 27–32 | Multiple passes |

| 3/8″+ | 400–600 | 280–380 | 28–34 | Preheat + back gouge |

How to Read and Adjust Any Manufacturer Chart Like a Pro

Every wire manufacturer (Lincoln, Hobart, ESAB, Harris) prints a slightly different chart on the spool label. Here’s my trick:

- Find your wire diameter first (usually .030, .035, .045, or .052)

- Find your material thickness column

- Look for self-shielded: start 10–15% lower than the chart says (wind kills heat outdoors)

- for dual shield: start dead center of the range

- Weld a 6″ test bead on scrap the same thickness, break it in a vice — if it breaks in the base metal you’re golden.

Most Common Flux Core Amperage Mistakes I See Every Week

Running too cold because “I’m scared of burn-through” — ends up with cold lap that snaps like a pretzel.

Setting voltage by ear instead of by the puddle — voltage controls bead width, not heat. Forgetting to bump amperage when you switch from flat to vertical-up — gravity fights you, so add 15–25 amps. Using a self-shielded chart for dual shield wire — you’ll be 50–70 amps too low and wonder why it won’t penetrate.

Best Wire Diameter for Beginners vs. Pros

.030″ — easiest to learn on, great for thin stuff and 120V machines, but runs out fast on thick material.

.035″ — the Goldilocks size. I run it 90% of the time. Works great from 18 gauge to 3/8″ single pass.

.045″ — beast mode for structural and heavy equipment. Needs at least a 200-amp machine to shine.

.052″ and bigger — pipe liners and shipyards mostly.

Machine Setup Checklist I Run Through Every Single Time

- Clean drive rolls and change them if they’re worn (V groove for flux core, never knurled!

- New liner if you’re over 12 ft or switching wire size

- Tip recessed about 1/4″ for self-shielded, stick-out 3/4″ max

- Polarity DCEP (electrode positive) unless you’re running Innershield NR-232

- Fan on high if it’s hot — keeps spatter from sticking inside the nozzle

Vertical-Up Settings That Actually Work

Self-shielded .035″ on 1/4″ plate: 190–210 amps, 19–20 volts, slight weave, travel 6–8 IPM.

Dual shield .045″: 260–280 amps, 27–28 volts, tight stringers, push slightly uphill.

I’ve welded 30 ft of 5/8″ bevel vertical with those exact numbers and passed X-ray every time.

Outdoor Welding in Wind: Drop Amps or Switch Wire?

If wind is over 5 mph with dual shield, you’re fighting a losing battle — porosity city. Either get wind breaks or switch to self-shielded and drop about 20 amps from the chart to tighten the arc. I keep a spool of NR-211-MP in the truck just for windy days.

How Temperature Affects Your Settings

Cold metal sucks heat like a sponge. Below 50 °F I bump wire feed 15–20% and usually preheat anything over 1/2″ to 150 °F with a rosebud. Hot summer days in Texas? Sometimes I drop 10 amps because the base metal is already 120 °F sitting in the sun.

Quick Reference Cheat Sheet for Your Phone

Screenshot this:

.035″ Self-Shielded

16ga → 140A

1/8″ → 190A

1/4″ → 240A

.045″ Dual Shield

1/8″ → 220A

1/4″ → 290A

3/8″ → 340A

Add 15–25A for vertical, subtract 15A for overhead.

Pro Tip Most Old Timers Won’t Tell You

Once you find the perfect setting on a certain machine, write the wire feed speed number on the panel with a Sharpie. Next time you roll up to that same welder you just spin the knob to that number and you’re welding in ten seconds — no test beads needed.

Wrapping UP

You now have every scrap of knowledge I’ve collected running flux core from Alaska pipelines to Florida humidity. Take this chart, stick it in your hood or phone case, and go lay down some of the cleanest beads of your life. Next time someone asks how you got that stack-of-dimes look with flux core, just smile and say “good amperage chart and a little practice.” Weld safe, weld strong, and I’ll see you out on the iron.

FAQs

Can you flux core weld without gas?

Absolutely. Self-shielded flux core (like NR-211-MP, NR-232, or Fabshield 21B) was literally invented for outside structural work where wind blows shielding gas away. You’ll get more spatter and smoke, but the weld is just as strong.

Is flux core stronger than MIG?

In many cases, yes — especially single-pass on thicker material. Flux core penetrates deeper and tolerates mill scale and rust better than solid wire with gas. That’s why you see it on almost every pipeline and bridge job.

What polarity for flux core?

99% of the time it’s DCEP (electrode positive). The only common exception is Lincoln Innershield NR-232 which runs DCEN for less penetration on thin stuff.

Why does my flux core welder spit so much?

Usually too much voltage or stick-out longer than 3/4″. Drop voltage one full volt and keep that wire sticking out 1/2″–3/4″ max. Also make sure you’re using flux core drive rolls — solid wire rolls will crush the tube.