When you’re just getting started with flux core welding, it can feel like the machine has a mind of its own — spatter flying everywhere, welds looking rough, and that wire feeding like it’s out to ruin your day. Don’t worry — we’ve all been there.

Flux core welding (FCAW) is one of the best ways for beginners to learn, especially if you’re working outside, on rusty or painted metal, or don’t have access to shielding gas like in MIG welding. The key is learning how to control your arc, set the right wire feed speed, and keep your travel angle steady.

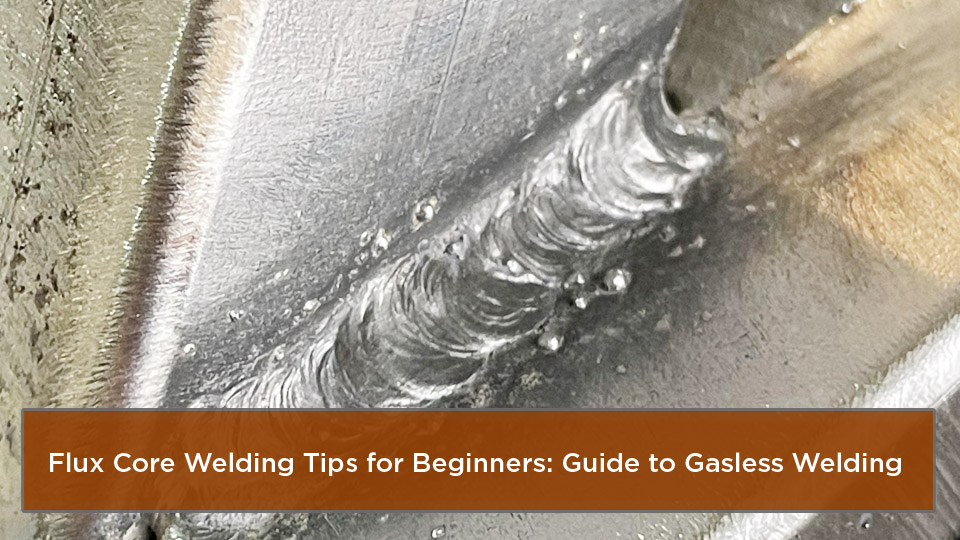

With a few solid techniques and some practice, you can go from messy, inconsistent beads to strong, clean welds that hold up under pressure. In this guide, I’ll share my best flux core welding tips for beginners — everything from machine setup to bead control — so you can skip the frustration and start welding with confidence.

Image by reddit

What Is Flux Core Welding and Why Bother with It as a Newbie?

You’re out in the yard fixing a gate, and a breeze hits just right to blow away your shielding gas—frustrating, right? Flux core welding, or FCAW as the pros call it, flips that script. It’s a semi-automatic process where the wire electrode has flux packed inside, like a self-contained shield that generates its own gas and slag to protect the weld pool from air and crud. No external gas bottle needed, which means you’re mobile and ready to go anywhere.

For beginners, this matters big time because it lowers the barrier to entry. You don’t need a fancy setup or perfect conditions to lay down a decent bead. I’ve used it on everything from mild steel brackets in a windy shipyard to hobby projects like a custom bike rack at home. The flux does the heavy lifting on shielding, so you focus on technique.

It penetrates deep into dirty or rusty metal, making it ideal for those “oh crap, it’s rusted” moments on older vehicles or structural repairs. Just remember, it’s best for thicker stuff—think 16 gauge and up—to avoid warping thin sheets.

Why does this beat sweating over a stick welder for your first tries? Simplicity. The continuous wire feed feels natural, like drawing with a hot pencil, and the high deposition rate means you cover ground fast. In shops across the US, from Texas oil fields to Midwest fab houses, flux core keeps production humming without constant cleanup breaks.

If you’re a student eyeing certification or a pro welder branching into portable jobs, mastering this builds confidence quick. One caveat: It kicks up more smoke than a barbecue, so ventilation is non-negotiable for clean lungs and clear heads.

Gear Up: Essential Equipment for Flux Core Welding on a Budget

Getting the right tools without breaking the bank. As someone who’s scavenged half my kit from yard sales, I know starting small works. At the heart is your welder: A basic 110V flux core machine like the Harbor Freight Eastwood or a Lincoln 140C handles most beginner needs. These crank out 90-140 amps, perfect for 1/8-inch mild steel plates or frames. Expect to spend $200-400; it’s an investment that pays off in frustration-free sessions.

Wire is next—grab E71T-GS .030-inch diameter for versatility. It’s self-shielded, meaning no gas, and welds carbon steel like a champ. A 2-pound spool runs $15-20 and lasts through practice runs. Don’t skimp here; cheap wire bird-nests and spits. For the gun, your welder’s included one works, but upgrade the contact tip to brass for better conductivity—$5 fix that saves headaches.

PPE isn’t optional; it’s your armor. Auto-darkening helmet ($50), leather gloves, flame-resistant jacket, and a respirator for those flux fumes. I’ve got scars from skipping the jacket once—lesson learned. Ground clamp? Ditch the flimsy one; a 300-amp bolt-style ($10) grips better on painted surfaces.

Prep tools round it out: Angle grinder with flap disc for cleaning, C-clamps or magnetic squares for holding pieces steady, chipping hammer and wire brush for slag removal. Total starter kit? Under $600 if you’re thrifty.

Pro tip from my early days: Test everything on scrap before your project. I once welded a toolbox lid with a dull tip—porosity city. Clean, sharp, and secure keeps you welding, not fixing.

| Essential Flux Core Gear | Why It Matters | Budget Pick |

|---|---|---|

| Welder (110V, 100+ amps) | Powers the arc reliably | Eastwood MIG 135 ($300) |

| Flux Core Wire (.030″) | Self-shielding for outdoors | Hobart E71T-GS ($18/spool) |

| Welding Gun & Tips | Feeds wire smoothly | Included + brass tips ($5) |

| PPE Kit | Protects from sparks/fumes | Lincoln helmet + gloves ($100) |

| Cleanup Tools | Removes slag fast | Hammer + brush set ($15) |

This table’s your cheat sheet—print it, pin it in the shop. With this, you’re set for joints that meet AWS basics without the pro price tag.

Setting Up Your First Flux Core Weld: A Step-by-Step Walkthrough

I’ve walked greenhorns through this a dozen times, and it always clicks when we go slow. Start in a flat position on clean mild steel butt joint, 1/4-inch thick. Clamp your pieces with 1/16-inch gap for expansion—too tight, and it warps.

Step one: Prep the metal. Grind off mill scale or rust to bright metal; flux core forgives dirt, but clean eats less wire. I learned this welding trailer hitches—rusty spots meant weak spots later.

Step two: Dial in the machine. Set polarity to DC electrode negative (DCEP? Wait, no—DCEN for flux core; check your manual). Voltage at 18-20V, wire speed 150-200 IPM for .030 wire. Too hot, you burn through; too cold, no fusion. Test on scrap: Aim for a steady sizzle, not popcorn.

Step three: Ground it right. Clip to clean metal close to the joint—extension cords kill amps. Pull the trigger; wire should feed smooth without spin.

Step four: Tack it up. Short bursts, 1/2-inch tacks every few inches. Let cool, check alignment. My first frame cracked from skipping this—tacks are your insurance.

Step five: Lay the bead. Hold 3/8-inch stickout, gun at 15-degree drag angle—pull toward you like reeling in a fish. Travel speed? Steady as a heartbeat, about 1/2-inch per second. Weave if filling gaps, straight for caps. Sparks fly forward; that’s normal.

Step six: Cool and clean. Chip slag with the hammer—it’s brittle, pops right off. Brush, then inspect: Convex bead means good penetration; flat or undercut? Adjust heat down.

That first bead? It’ll look like a drunk snake, but practice evens it. I spent a weekend on angle iron runs; by Sunday, I had shop-worthy fillets. Rinse, repeat, and you’re building muscle memory for verticals or overheads next.

Nailing Machine Settings: Tips for Mild Steel, Thicker Plates, and More

Settings are your secret sauce—get ’em wrong, and you’re chasing porosity like I did on a rainy fab job. For beginners, start with mild steel, the workhorse of US shops. On 1/8-inch plate, 18V and 180 IPM gives a puddle that’s Goldilocks: Not too runny, not too stiff.

Thicker stuff, say 3/8-inch beams? Bump to 22V, 250 IPM. Preheat if under 50°F to dodge cracks—I’ve snapped cold welds in winter. For galvanized? Flux core eats the zinc, but ventilate extra; fumes hit like bad coffee.

| Material Thickness | Voltage | Wire Speed (IPM) | Stickout | Notes |

|---|---|---|---|---|

| 1/16″ – 1/8″ | 16-18V | 120-160 | 1/4″ | Light drag, fast travel to avoid burn-through |

| 1/4″ – 3/8″ | 19-22V | 180-250 | 3/8″ | Weave for fillets; check for undercut |

| 1/2″+ | 23-26V | 260-350 | 1/2″ | Preheat, multiple passes; slag between layers |

This chart’s from years tweaking on the fly—use it, then tweak based on sound. Listen: Crisp bacon sizzle is gold; hissing means too much voltage. For hobbyists, apps like Miller’s calculator dial it precise, but scrap tests trump all. One time, I over-volted on thin sheet for a gate—melted right through. Dial back 10% for verticals; gravity pulls the puddle.

Joint prep ties in: Bevel thick edges 30 degrees for V-grooves, ensuring filler hits root. Filler compatibility? Stick to ER71T-1 for low-alloy steels; mismatches cause cracks. These tweaks turn “eh” welds into ones that pass shop inspections.

Flux Core Welding vs. MIG: Breaking Down the Choices for Your Projects

Ever wonder why flux core when MIG’s everywhere? I switched mid-career for outdoor gigs, and it was eye-opening. MIG uses gas—argon mix—for clean, spatter-free beads indoors. Flux core? Self-shielded, so wind-proof and dirt-tolerant, but with slag to chip.

Pros of flux core: Portability—no tank to lug on ladders. Deeper penetration for structural stuff like I-beams in construction. Cost-efficient; wire’s cheaper long-run. Cons: Fiddly cleanup, more fumes. MIG wins on aesthetics—shiny beads for visible work like furniture.

| Feature | Flux Core | MIG |

|---|---|---|

| Shielding | Built-in flux | External gas |

| Best For | Outdoors, dirty metal | Indoors, clean finishes |

| Penetration | Deep, forgiving | Shallow, precise |

| Cleanup | Slag chipping | Minimal spatter |

| Beginner Ease | High (less setup) | Medium (gas management) |

For DIYers, flux core’s your trailblazer—fix that fence post in a gale. Pros lean MIG for production lines per AWS D1.1 codes. Me? I keep both; flux for field, MIG for bench. Choose based on your shop: Windy? Flux. Pristine? MIG.

Dodging Pitfalls: Common Beginner Mistakes in Flux Core Welding

The stories I could tell—my apprentice once pushed the gun like MIG and got a spaghetti mess. Biggest no-no: Wrong technique. Always drag; pushing traps slag, weakens the joint. Fix? Retrain your grip—forearm pull, steady.

Bird-nesting wire? Too much tension or bad drive rolls. Loosen 1/4 turn, clean the liner. I fixed this weekly early on; now, I inspect pre-spool.

Burn-through on thin metal: Crank voltage down, speed up. Porosity from damp wire? Bake it at 250°F for an hour—flux hates moisture. And skipping cleanup? Multi-pass nightmares; chip every layer or risk inclusions.

Safety slip: No respirator in a closed garage—cough city. One fume-filled night taught me fans and fresh air save trips to the doc. Track these, and your failure rate drops 80%. Journal your runs; patterns emerge.

Safety Essentials: Keeping Yourself Whole While You Weld

Welding’s a blast, but respect the fire. Flux core amps up fumes—zinc oxide from galvanized hits hard—so hook up a shop vac with HEPA or crack windows. I’ve hacked a box fan filter; works wonders.

PPE ritual: Helmet down, gloves on, no loose sleeves. Sparks bounce like popcorn; I’ve singed jeans ignoring this. Ground faults? Test cables monthly—shocks aren’t fun.

Fire watch: Wet rags nearby, extinguisher charged. Post-weld, patrol for smolders. For students or site workers, OSHA 1910.252 mandates this; follow it home too. Hydrate, take breaks—heat builds fast. Safe welder’s a long-time welder; I’ve seen shortcuts hospitalize folks.

Leveling Up: Pro Tips for Cleaner Beads and Stronger Joints

Once basics click, finesse shines. For verticals, whip upward—shorten stickout to 1/4-inch, drop amps 15%. Overhead? Stringers only, low weave; gravity’s a beast. I nailed a ceiling joist repair this way—held 500 pounds no sweat.

Slag control: Angle your chip hammer right; it shears clean. For aesthetics, grind flush post-brush—matches MIG looks.

Anecdote time: On a rush barn repair, I layered passes wrong—cold laps everywhere. Now, I preheat and interpass cool to 150°F. Experiment with wires: E71T-8 for galvanized, less spatter.

Travel speed hacks: Mark your gun with tape for consistency. Sound-check: Steady hum means balance. These nuggets turned my hobby welds pro-grade.

Wrapping Up

Flux core welding tips for beginners that cut through the noise and get you building. From grasping the self-shielding magic to dialing settings that stick, you’ve got the roadmap to welds that hold under torque or time. This isn’t just theory; it’s the stuff that keeps trailers towing and frames framing across American backyards and job sites.

You’re more prepared now because you know the why behind the drag, the prep that prevents pops, and the safety that sustains. Grab that scrap, spool up, and lay a bead—confidence comes with the first clean run.

FAQs

Can Beginners Really Handle Flux Core Welding Without Training?

Absolutely—it’s one of the most forgiving processes out there. With basic gear and these tips, you’ll tack and bead on day one. Just practice on scrap to build hand-eye sync; formal classes amp it up, but DIY works for hobbyists.

What’s the Best Flux Core Wire for Starter Projects?

Go with .030-inch E71T-GS self-shielded—versatile for mild steel up to 1/4-inch, low spatter, and easy to find at Tractor Supply or online. Avoid exotics till you nail the basics.

Do I Need Shielding Gas for Flux Core?

Nope, that’s the beauty—self-shielded flux generates its own protection. Gas-shielded versions exist for cleaner indoor work, but beginners thrive gasless for portability.

How Do I Fix Porosity in My Flux Core Welds?

Usually moisture or dirt—dry your wire, clean metal bright, and check for drafts. Reweld after grinding out the bad spots; consistent drag helps too.

Is Flux Core Strong Enough for Structural Repairs?

Yes, when done right—it meets AWS codes for carbon steel frames. Deep penetration shines, but inspect for full fusion and consult codes for load-bearing stuff like bridges.