Welding thin metal with an arc welder is one of those jobs that’ll humble you fast. I’ve had plenty of moments where I struck an arc on thin sheet metal, only to watch it blow a hole before I could even steady my hand. Stick welders run hot, and without good arc control, the metal thickness just works against you. But here’s the good news — with the right rod choice, proper joint prep, lower amperage, and a few tricks to manage heat buildup, you can get clean, strong welds on thin-gauge steel using a stick welder.

The key is technique, not power. In this guide, I’ll break down exactly how to weld thin metal with an arc welder the smart way, so you can avoid burn-through, reduce warping, and get those smooth, controlled beads you’re after.

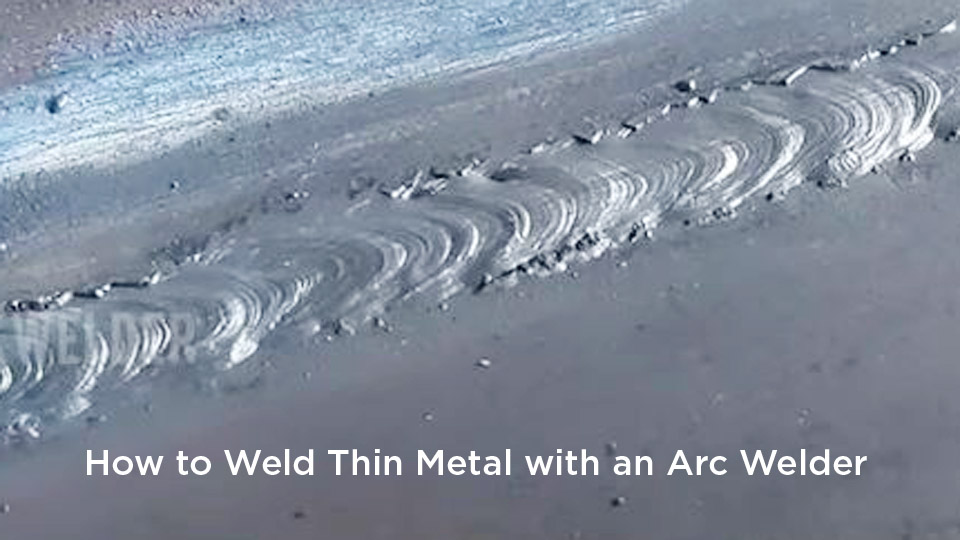

Image by yeswelder

Understanding Arc Welding for Thin Metal

When I first started, I thought arc welding was all about cranking up the power and laying down beads, but thin metal flips that script. Arc welding, especially stick welding, uses an electric arc to melt the base metal and electrode, creating a weld pool that’s protected by flux. For thin stuff—say, 18-gauge steel or thinner— the key is controlling that intense heat to avoid melting right through.

This process shines when you don’t have gas setups for MIG or TIG, making it ideal for outdoor jobs or basic shop work. I use it on thin metal when I’m fixing farm equipment or prototyping brackets, where portability matters more than perfect cosmetics.

Why choose it over other methods? It’s rugged, works on dirty surfaces, and doesn’t need shielding gas, which cuts costs for hobbyists. But remember, it’s not as forgiving on thin stock, so knowing when to use it—like for structural repairs versus cosmetic panels—keeps you efficient.

In practice, thin metal demands shallow penetration to maintain integrity. I’ve seen pros swear by it for quick fixes on trailers, but students often struggle until they grasp heat management. Semantic terms like “shallow fusion” or “minimal distortion” come up a lot in shop talk, reminding us why precision pays off in safety and longevity.

Choosing the Right Rod for Welding Thin Metal

Picking the electrode is where many folks trip up, and I’ve done it myself early on. For thin metal with an arc welder, go for rods that offer shallow penetration and easy arc starts. My go-to is the E6013 rod—it’s versatile, runs smooth on both AC and DC machines, and doesn’t dig deep like a 6010.

Why E6013? It deposits metal gently, which is crucial for avoiding holes in thin sheets. I prefer 1/16-inch diameter for most thin work; it’s small enough to run at low amps without overpowering the material. On a job site once, I was patching 20-gauge galvanized steel, and switching to 6013 saved the day—no more burn-through, just clean beads.

Other options include 7014 for a bit more fill, but stick with smaller sizes like 3/32-inch max. Avoid deep-penetrating rods unless you’re bridging gaps. In US shops, these align with AWS standards, ensuring compatibility with common steels. Pro tip: Bake your rods if they’re moist; it prevents porosity that can weaken thin welds.

I’ve tried cheaper off-brand rods, but they often splatter more, messing up thin edges. Invest in quality like Lincoln or Hobart for consistent results. When prepping, match the rod to your metal type—mild steel loves 6013, while stainless might need something specialized.

Preparing Your Workspace and Materials for Thin Metal Welding

Prep work is half the battle, and I’ve learned that the hard way after rushing and regretting it. Start by cleaning the metal—remove rust, paint, or oil with a wire brush or grinder. Thin metal picks up contaminants fast, leading to porous welds that fail under stress.

Joint prep is key: Opt for lap joints over butt joints on thin stock. They provide more surface area for fusion without needing perfect edge alignment. I always bevel edges slightly on thicker thin metal, say 16-gauge, to improve penetration without excess heat.

Set up your workspace with good ventilation—fumes from flux can build up quick in a garage. Clamp your pieces tightly; any gap invites burn-through. I use C-clamps or magnets to hold everything steady, mimicking how I’d train a new guy on site.

For material compatibility, ensure your thin metal isn’t galvanized if possible; the zinc fumes are nasty and can crack welds. If it is, grind off the coating first. In real applications like auto body repair, this prep ensures welds meet safety codes without warping panels.

One anecdote: I was helping a buddy fabricate a toolbox from 18-gauge sheet, and skipping the clamp step led to distortion. We fixed it by reheating and hammering, but proper prep would’ve avoided that headache.

Step-by-Step Guide to Welding Thin Metal with an Arc Welder

I’ll walk you through like I’m showing you in my shop.

First, set your machine. For DC welders, switch to DCEN polarity—it puts less heat in the base metal, perfect for thin stuff. AC works but is trickier with arc stability.

Select your rod—1/16-inch 6013—and dial amps low. For 20-gauge steel, start at 40-50 amps; bump to 50-60 for 18-gauge. Test on scrap to fine-tune.

Strike the arc: Tap or scratch gently to avoid sticking. Once lit, hold a short arc length, about the rod’s diameter, and move fast.

Technique: Use stitch welding—short bursts of 1/2 to 1 inch, then pause to cool. This prevents heat buildup. Drag the rod at a 15-degree angle, pushing the puddle forward for better control.

For vertical welds, go downhill if possible; gravity helps with thin metal. On laps, weld the edge first to tie in.

Cool between passes: I blow compressed air or use a damp rag (not on hot metal) to dissipate heat. Repeat until the joint’s filled.

Post-weld: Chip slag, inspect for cracks, and grind if needed. In a real job like fencing repair, this method ensures straight, strong seams without holes.

Practice this sequence on scrap—I’ve burned through boxes of rod perfecting it, and it pays off in clean, integral welds.

Machine Settings for Different Thin Metal Thicknesses

Settings vary by thickness, and I’ve dialed them in over years of trial and error. For 24-gauge (super thin), keep amps at 30-40 with 1/16-inch rod; any higher, and you’ll punch holes.

On 20-gauge, 40-50 amps works well with DCEN, fast travel speed. For 16-gauge, you can go 50-70 amps, but still stitch to avoid warping.

Aluminum thin stock? Use specialized rods and higher amps, around 60-80, but it’s finicky—stick to steel if you’re new.

In comparisons:

| Thickness | Recommended Amps | Rod Size | Polarity | Notes |

|---|---|---|---|---|

| 24-gauge | 30-40 | 1/16″ | DCEN | Ultra-low heat, tacks only |

| 20-gauge | 40-50 | 1/16″ | DCEN/AC | Stitch welds essential |

| 18-gauge | 50-60 | 1/16″-3/32″ | DCEN | Balance speed and fusion |

| 16-gauge | 60-70 | 3/32″ | DCEN | Allows slight weaving |

These are starting points—adjust based on your machine. I once tuned a Hobart stick welder for 18-gauge brackets at 55 amps, and it fused perfectly without distortion.

For stainless, drop amps 10-20% to account for heat retention. Always test; machines vary, but these align with US standards for safe, efficient welding.

Common Mistakes When Welding Thin Metal and How to Fix Them

I’ve made every mistake in the book, so let’s save you the frustration. Top one: Too much heat leading to burn-through. Fix: Lower amps, speed up, and use heat sinks like copper backing bars—they absorb excess energy.

Warping from uneven heating? I did that on a gate repair once—metal bowed like a banana. Solution: Tack evenly, weld in sections alternating sides, and clamp to a flat surface.

Sticking electrodes? Happens on low amps. Strike firmer or clean your rod tip. Porosity from dirty metal? Always degrease first.

Another: Ignoring joint type. Butt joints on thin metal often fail; switch to laps for forgiveness. If you blow a hole, stop, grind clean, and patch with a short tack—don’t chase it.

In shop practice, these fixes build weld integrity, preventing costly reworks. For students, logging mistakes helps; I keep a notebook for settings that bombed.

Safety Considerations for Arc Welding Thin Metal

Safety isn’t optional—I’ve seen sparks turn into fires in cluttered shops. Always wear leather gloves, a helmet with proper shade (10-12 for stick), and flame-resistant clothing. Thin metal heats fast, so watch for hot edges that burn skin.

Ventilate well; flux smoke can irritate lungs. Use a respirator if indoors. Ground your machine properly to avoid shocks, especially on damp floors.

For thin work, flying slag is common—protect your eyes and nearby flammables. In US codes, PPE is mandated for pros, but even DIYers should follow. One time, a stray spark ignited rags; now I clear a 10-foot radius.

Keep fire extinguishers handy, and never weld near fuels. This keeps you safe while focusing on technique.

Pros and Cons of Stick Welding Thin Metal Compared to Other Methods

Stick welding thin metal has its place, but let’s compare.

Pros of stick: No gas needed, portable for field work, handles wind, cheap setup. I’ve used it on remote sites where MIG would’ve failed.

Cons: Harder heat control, more slag cleanup, rougher beads. Vs. MIG: MIG’s easier on thin with wire feed, but requires gas and is pricier. TIG offers precision but needs skill and argon.

In tables:

| Method | Pros for Thin Metal | Cons for Thin Metal |

|---|---|---|

| Stick (SMAW) | Portable, no gas, rugged | High burn-through risk, slag |

| MIG (GMAW) | Easy control, clean beads | Needs gas, spatter on thin |

| TIG (GTAW) | Precise heat, no filler issues | Slow, requires foot pedal skill |

For hobbyists, stick’s cost-efficient; pros might mix methods. In real apps like auto repair, stick fixes where others can’t reach.

Tools and Equipment Essentials for Thin Metal Arc Welding

Beyond the welder, grab a chipping hammer for slag, wire brush for cleaning, and angle grinder for prep. I swear by a good stinger—comfortable ones reduce fatigue on long days.

For thin work, heat sinks are game-changers; copper plates dissipate heat fast. Clamps and jigs keep joints tight.

US brands like Miller or Lincoln machines handle low amps well. Students, start with a basic inverter welder—they’re lightweight and stable.

Anecdote: On a fabrication job, my old tombstone welder struggled on thin; upgrading to an inverter smoothed everything out.

Advanced Techniques for Better Welds on Thin Metal

Once basics click, try pulsing—manually start/stop the arc for heat control. It’s like TIG without the setup.

For curves, like exhaust bends, use backing rings inside for support. I fabricated a manifold this way, no leaks.

On galvanized, strip zinc first or use ventilation. For strength, add filler compatible with base—ER70S for steel.

In industry, these ensure code compliance; for DIY, they elevate projects from functional to pro-level.

Troubleshooting Weld Quality on Thin Metal

Weak beads? Check fusion—slow down slightly but not too much. Cracks? Overheating; cool more.

Discoloration means excess heat; reduce amps. I troubleshoot by sectioning test welds—cut and inspect penetration.

For hobbyists, this builds trust in your work, preventing failures in use.

Real-World Applications of Welding Thin Metal with Arc

From DIY gates to pro HVAC, thin welding’s everywhere. I repaired a trailer frame—thin crossmembers fused strong without weight add.

Students practice on scrap for certs; workers use it for quick patches. Cost-wise, it’s efficient, using less filler.

One story: Helped a friend weld thin panels for a smoker—perfect seals, no smoke leaks, all with stick.

Key Takeaways and Why You’re Ready to Weld Thin Metal

Low amps, small rods like 6013, DCEN polarity, stitch techniques, and solid prep are your foundations for welding thin metal with an arc welder. You’ve got the why—safety, strength, efficiency—and the how, from settings to fixes.

Whether you’re a DIYer patching a mower deck, a student prepping for trade school, or a pro on site, these insights arm you against common pitfalls like burn-through or warping.

You’re more prepared now because you’ve seen the real-world angles, not just theory. Grab some scrap, dial in your machine, and start tacking—confidence comes with that first solid bead. Always weld a test piece in the same position as your project; it catches issues before they ruin good material.

FAQs

Can You Weld Very Thin Metal Without Burning Through?

Absolutely, but it takes finesse. Use the lowest amps your machine allows, like 30-40 for 24-gauge, with 1/16-inch 6013 rod and DCEN. Stitch weld in short bursts, cool between, and back with copper to sink heat. Practice avoids holes every time.

What’s the Best Polarity for Stick Welding Thin Steel?

DCEN is best for DC machines—it minimizes heat in the base metal. AC works for basic welders but can be unstable at low amps. I’ve switched polarities mid-job and seen DCEN reduce burn-through instantly.

How Do You Prevent Warping When Arc Welding Thin Sheets?

Tack evenly first, weld in alternating sections, and use clamps on a flat table. Fast travel speed and pauses for cooling help too. On a thin panel once, this kept everything straight as an arrow.

Is Stick Welding Better Than MIG for Thin Metal in Outdoor Settings?

Stick wins outdoors—no gas to blow away, and it’s portable. But MIG’s easier indoors for clean beads. For wind-prone jobs like fence repairs, stick’s my pick every time.

What Rod Size Should Beginners Use for Thin Metal Arc Welding?

Start with 1/16-inch—it’s forgiving at low amps and controls heat well. Pair with E6013 for smooth runs. Beginners, test on scrap to build feel without wasting good stock.