Dialing in a Lincoln welder can feel like guesswork when you’re jumping between different metal thicknesses, wire sizes, and welding processes. I’ve had plenty of days where I’d run a bead, look at the spatter or lack of penetration, and think, “Yep… settings are off again.”

That’s when I really started relying on a Lincoln welder settings chart — and it completely changed how quickly I could get dialed in.

Whether you’re running MIG, TIG, or flux core, the right combo of voltage, wire feed speed, amperage, and travel speed makes a massive difference in weld quality. Get it right, and your arc runs smooth, your puddle stays predictable, and your bead ties in perfectly without wasting filler or overheating the metal.

In this guide, I’ll walk you through the exact settings you can use for common Lincoln machines — plus how to fine-tune them on the fly so every weld looks (and holds) like it should.

Why Correct Settings Actually Save Your Butt (and Your Wallet)

I’ve watched grown men cry on a job site because they burned through a ¼-inch plate on a structural beam with the heat cranked too high. Not only did they have to grind it out and start over, the inspector red-tagged the whole piece. That’s thousands of dollars and a week behind schedule because somebody “felt” the settings instead of looking at a chart.

Proper amperage keeps you from:

- Burning through thin metal

- Getting lack-of-fusion defects that fail inspection

- Wasting rods or wire because the arc is unstable

- Creating excessive spatter that you’ll spend an hour chipping off later

I learned that lesson the hard way on a 6061 aluminum job for a race car shop. Too hot and you turn beautiful plate into Swiss cheese. Too cold and the puddle won’t wet out. The chart fixed that in about thirty seconds.

Understanding Lincoln’s Machine Families – Because Not All Red Boxes Are the Same

Lincoln makes a ton of machines, and the same rod doesn’t run the same on all of them. Here’s the quick breakdown I tell every helper:

- Square Wave TIG series (200, 210, 275, 375) – incredible arc control, great for aluminum

- Power MIG series (210 MP, 260 MP, 360 MP) – the MIG workhorses most fab shops live on

- Idealarc and Precision TIG – old-school transformer machines still running in half the vo-tech shops in America

- Ranger engine drives – what you’ll find on pipeline and construction sites

Each family likes slightly different voltage and wire-speed sweet spots. My chart is built around the machines I’ve personally beaten to death: Power MIG 210 MP, Square Wave TIG 200, and the good old Idealarc 250 stick machine.

Stick Welding (SMAW) Settings I Actually Use Every Day

I still run 7018 more than anything else because it’s cheap, forgiving, and passes every bend test I’ve ever seen.

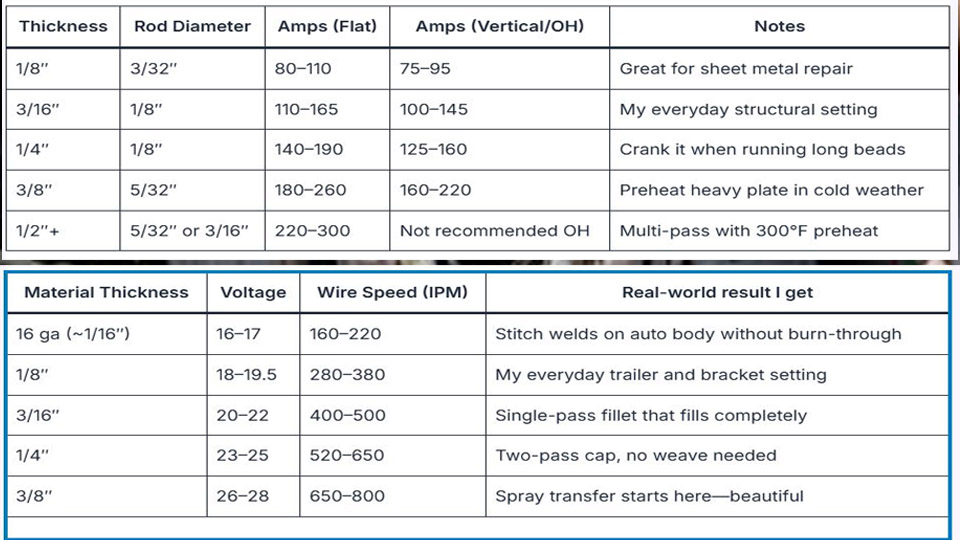

E7018 Settings for Mild Steel – The “Go-To” Chart on My Toolbox

| Thickness | Rod Diameter | Amps (Flat) | Amps (Vertical/OH) | Notes |

|---|---|---|---|---|

| 1/8″ | 3/32″ | 80–110 | 75–95 | Great for sheet metal repair |

| 3/16″ | 1/8″ | 110–165 | 100–145 | My everyday structural setting |

| 1/4″ | 1/8″ | 140–190 | 125–160 | Crank it when running long beads |

| 3/8″ | 5/32″ | 180–260 | 160–220 | Preheat heavy plate in cold weather |

| 1/2″+ | 5/32″ or 3/16″ | 220–300 | Not recommended OH | Multi-pass with 300°F preheat |

Pro move: Always run 7018 one size smaller than you think you need. A 1/8″ rod at 140 amps makes a prettier bead than a 5/32″ at 200 amps 9 times out of 10.

E6010 and E6011 – The Dirty, Fast Root Pass Kings

| Thickness | Rod | Amps (DC+) | Whip or no whip? |

|---|---|---|---|

| Any | 6010 | 75–125 | Heavy whip on root |

| Any | 6011 | 80–130 | Straight drag on AC boxes |

6010 digs like crazy—perfect for rusty farm equipment or pipe. 6011 on an old tombstone welder with AC is still my favorite for quick fence repairs.

MIG Welding Settings That Don’t Lie

Short-circuit MIG on the Power MIG 210 MP with .035 ER70S-6 and C25 gas (75/25):

| Material Thickness | Voltage | Wire Speed (IPM) | Real-world result I get |

|---|---|---|---|

| 16 ga (~1/16″) | 16–17 | 160–220 | Stitch welds on auto body without burn-through |

| 1/8″ | 18–19.5 | 280–380 | My everyday trailer and bracket setting |

| 3/16″ | 20–22 | 400–500 | Single-pass fillet that fills completely |

| 1/4″ | 23–25 | 520–650 | Two-pass cap, no weave needed |

| 3/8″ | 26–28 | 650–800 | Spray transfer starts here—beautiful |

If your bead looks like a worm pile, drop voltage 1 volt and bump wire speed 50 IPM. Fixed 95% of the ugly welds I see from new guys.

Aluminum MIG (Spool Gun) Settings I Trust

.035 5356 wire, 100% argon, Power MIG 210 MP with spool gun:

| Thickness | Voltage | Wire Speed | Travel Speed Tip |

|---|---|---|---|

| 1/8″ | 19–21 | 380–450 | Push at 15–20 IPM, 15° angle |

| 3/16″ | 22–24 | 480–550 | Two passes, clean between |

| 1/4″ | 24–26 | 550–650 | Preheat to 200°F if it’s cold out |

Common mistake: running aluminum like steel. You have to push, not drag, or you’ll get black soot everywhere.

TIG Settings for Mild Steel, Stainless, and Aluminum

Square Wave TIG 200 is my baby.

Mild Steel DCEN – 3/32″ 2% Lanthanated Tungsten

| Thickness | Amps | Filler (ER70S-2) | Gas (100% Argon) | Cup Size |

| 1/16″ | 60–90 | 1/16″ | 15–20 CFH | #7 or #8 |

| 1/8″ | 100–140 | 3/32″ | 15–20 CFH | #8 |

| 1/4″ | 180–220 | 1/8″ | 20–25 CFH | #8 or #10 |

304 Stainless – Same Tungsten, Straight Argon

Drop the amps 10–15% from mild steel and use 308L filler. Keep the puddle small or you’ll sugaring on the back side.

Aluminum AC Balance 70–75% EN, Frequency 120–150 Hz

| Thickness | Amps | Filler (4043 or 5356) | Balance | Cleaning action I want |

|---|---|---|---|---|

| 1/8″ | 120–150 | 3/32″ 4043 | 72% EN | Just enough to shine |

| 3/16″ | 180–220 | 1/8″ 5356 | 70% EN | Heavy cleaning on dirty cast |

I run 4043 on everything except 6061-T6 thick stuff—then I switch to 5356 so it doesn’t crack later.

How to Build Your Own “Forever” Settings Chart

Here’s exactly what I did:

- Buy a 12×18″ piece of 16 ga sheet metal.

- Scribe your most-used settings with a sharp tungsten.

- Weld over the lines with 7018 low-hydrogen (it sticks forever).

- Hang it on the wall or weld a magnet on the back of your toolbox.

It’s bulletproof, grease-proof, and when the new guy asks “what do I run this at?” you just point.

Most Common Settings Mistakes I Still See (And How to Fix Them)

- Running too cold because “I’m scared of burn-through” → lack of fusion, fails ultrasound every time

- Cranking voltage way up to “make it run smoother” → excessive spatter and undercut

- Never cleaning the base metal → porosity city

- Using the same settings in 30°F weather as you do in July → arc gets unstable when it’s cold

- Ignoring joint fit-up → no chart in the world fixes a 3/16″ root opening on a butt joint

Quick Cheat Sheet I Keep in My Wallet

- 1/8″ mild steel fillet → 1/8″ 7018 at 135 amps or .035 MIG at 19.5V / 350 IPM

- 3/16″ mild steel → 1/8″ 7018 at 160 amps or MIG 22V / 480 IPM

- 1/8″ aluminum TIG → 130 amps, 3/32″ 4043, 72% EN balance

- Root pass on pipe → 1/8″ 6010 at 90 amps, heavy whip

Final Word From a Guy Who’s Burned Thousands of Pounds of Rod

Take this chart, tweak it for your own machine and hands, then beat it up in the real world. In six months it’ll be better than anything you download because it’ll be yours. The welds you lay down tomorrow will be cleaner, stronger, and faster because you stopped guessing and started knowing.

Once a month, run one bead on scrap with your “standard” setting. If it doesn’t look exactly like it did last month, check your ground clamp, cables, or liner. Machines drift—good welders catch it before the inspector does.

FAQs

What polarity do I use for 7018?

Always DC+ (reverse polarity). Running 7018 on DC- or AC gives you a trash arc and tons of spatter.

Can I use the same settings on Lincoln as I do on Miller?

Close, but not exact. Lincoln machines usually like about ½–1 volt higher than Miller for the same wire and thickness. Test on scrap.

Why does my MIG bead look ropey and convex?

You’re running too cold. Bump voltage 1 volt or drop wire speed 50 IPM. One of those two fixes it every time.

Is 100% argon okay for mild steel MIG?

It’ll work but you’ll get a stiff, ropy bead and deeper penetration than you want most of the time. Stick with 75/25 or 80/20 C25.

How do I know if my TIG cleaning action is right on aluminum?

The puddle should look wet and shiny with just a faint frosty edge. If it’s got black soot, push more EP (less cleaning). If the tungsten is balling up and the plate isn’t etching, add more cleaning (more EP).