When I first started dialing in my MIG settings, I wasted a ton of time guessing. I’d crank up the voltage, slow down the wire feed, then crank it back again — trying to stop the weld from either burning through thin metal or piling up like cold bubble gum.

That’s when I learned how valuable a simple MIG welding wire speed and voltage chart really is. The right balance between voltage, wire feed speed, metal thickness, and filler wire size can turn a rough, spattery weld into a clean, strong bead with good penetration.

Whether you’re running ER70S-6 wire, working on mild steel, or switching between short-circuit and spray transfer, proper settings save gas, reduce rework, and make your welds look like they came from a pro. I’ll share chart-based settings you can trust, plus tips to fine-tune your machine on the fly for perfect beads every time.

Why Wire Speed and Voltage Actually Matter More Than Your Trigger Finger

Voltage controls heat and arc length. Wire speed controls how much filler metal you’re shoving into that puddle. Too much voltage and you get a flat, wide, ugly bead with no penetration. Too little and the arc stumbles, spatters like crazy, and you’re basically just gluing two pieces of metal together.

Match wire speed wrong and you’ll either burn through thin stuff or starve the puddle on thick plate and get cold lap. I’ve seen brand-new tech school grads chase their tail for an hour because they thought “close enough” was good enough. It’s not.

A good chart, your material thickness, and about ten test beads on scrap is all that stands between you and welds you’d proudly put your name on.

How to Read a MIG Wire Speed and Voltage Chart Like a Pro

Most charts you find from Lincoln, Miller, or ESAB are laid out the same way: material thickness down the side, wire diameter across the top, then two columns—one for voltage, one for wire feed speed (usually in inches per minute, IPM).

Some charts also list amperage because that’s what actually melts the wire, but your machine displays wire speed, not amps, so that’s what we focus on.

Here’s the trick a lot of guys miss: the chart gives you a range, not an exact number. Start in the middle of the range, weld a straight line on scrap the same thickness as your project, and adjust from there. If the bead is ropy and tall, drop the wire speed 20-30 IPM or bump voltage half a volt.

If you’re getting excessive spatter and the arc sounds angry, you’re probably running too cold—add wire speed first, then voltage.

Best Starting Settings for ER70S-6 Wire on Mild Steel

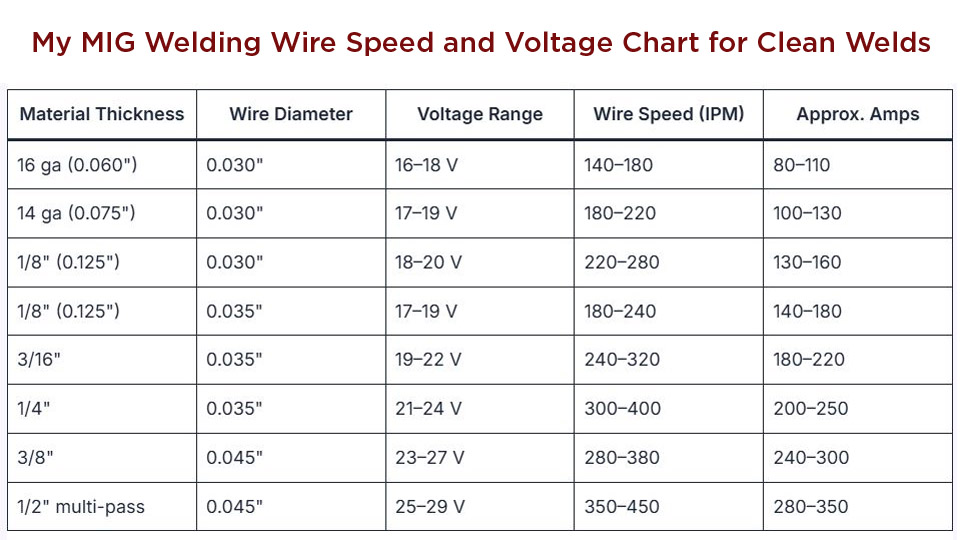

I’m throwing the numbers I actually use in my shop every day. These are for short-circuit transfer with 75/25 gas (argon/CO2)—what 90% of us run.

| Material Thickness | Wire Diameter | Voltage Range | Wire Speed (IPM) | Approx. Amps |

|---|---|---|---|---|

| 16 ga (0.060″) | 0.030″ | 16–18 V | 140–180 | 80–110 |

| 14 ga (0.075″) | 0.030″ | 17–19 V | 180–220 | 100–130 |

| 1/8″ (0.125″) | 0.030″ | 18–20 V | 220–280 | 130–160 |

| 1/8″ (0.125″) | 0.035″ | 17–19 V | 180–240 | 140–180 |

| 3/16″ | 0.035″ | 19–22 V | 240–320 | 180–220 |

| 1/4″ | 0.035″ | 21–24 V | 300–400 | 200–250 |

| 3/8″ | 0.045″ | 23–27 V | 280–380 | 240–300 |

| 1/2″ multi-pass | 0.045″ | 25–29 V | 350–450 | 280–350 |

These numbers have saved my butt on everything from trailer frames in Texas to food-grade stainless carts in California.

Choosing the Right Wire Diameter for the Job

I keep three spools on the bench at all times: 0.030″, 0.035″, and 0.045″. Here’s when I grab each one:

- 0.030″ – Sheet metal, car panels, anything under 1/8″. Runs smooth, low spatter, forgiving on thin stuff.

- 0.035″ – My go-to 90% of the time. Perfect balance for 1/8″ up to 3/8″ structural work.

- 0.045″ – Heavy plate, multi-pass fillets, anything where I need serious deposition and I’m not worried about burning through.

Running 0.023″ sounds cool on paper, but unless you’re doing real autobody or you’ve got a $5,000 synergic machine, it’s more trouble than it’s worth for most of us.

Gas Choices and Why 75/25 Rules the Lower 48

Straight CO2 is cheaper and digs deeper, but the spatter will make you want to throw your welder in the lake. 75/25 (75% argon, 25% CO2) gives you a smooth arc, way less spatter, and still enough penetration for structural work.

I only switch to 90/10 or straight argon when I’m spraying stainless or aluminum. Keep your bottle above 10 CFH and below 25 CFH—any more and you’re just wasting money and sucking air into the shield.

Common Mistakes I Still See on Job Sites (And How to Fix Them Fast)

Running voltage too high for the wire speed – You get that flat, washy bead that looks wet but has zero penetration. Fix: drop voltage one full volt, then creep wire speed up until the arc smooths out.

Forgetting to adjust for vertical or overhead – Gravity pulls the puddle down, so drop wire speed 15–25% and run a touch colder voltage. You’ll thank me when you’re not fighting drips.

Using the chart for 100% CO2 when you’re on 75/25 – The chart numbers will be too hot and you’ll burn through everything. Start 1–2 volts lower and 30–50 IPM slower.

Trusting the door chart on a twenty-year-old machine – Those charts lie after the contact tip wears or the drive rolls get sloppy. Always verify with test beads.

Setting Up Your Machine Step by Step (The Way I Teach Every New Guy)

- Clean the base metal. Grind off mill scale or rust until it’s shiny.

- Pick your wire and load it—make sure the drive rolls match the wire diameter and the tension is just snug (too tight flattens the wire and causes feeding issues).

- Set gas to 20 CFH for 75/25.

- Look at your thickness, pick the row on the chart, set voltage smack in the middle of the range.

- Set wire speed 10–20 IPM below the middle of the range to start cold.

- Strike an arc on scrap, run a 6-inch bead.

- Look at the bead. Too tall? Add wire speed. Spattery? Add voltage or wire speed. Burn-through? Drop both.

- Repeat until it sounds like bacon frying and the bead stacks nice and even.

- Write your final settings on the scrap with soapstone—trust me, you’ll forget by tomorrow.

Spray Transfer vs Short Circuit: When to Flip the Switch

Most hobby and light fab machines only do short-circuit. That’s the pop-pop-pop sound under about 24–25 volts. Once you get above 26–27 volts with 0.035″ or 0.045″ wire you can flip into spray transfer—super smooth, almost no spatter, looks like a laser. Only works on 3/16″ and thicker because the heat is intense. I use spray on heavy equipment repairs when I want it pretty and fast.

Aluminum MIG Settings (Because Someone Always Asks)

4043 wire, 100% argon, 3/8″ stickout, and run it hot. For 1/8″ 6061 I’m usually around 22–24 volts and 380–450 IPM on 0.035″ 4043. Push the puddle, don’t whip or weave like steel. The chart on the side of a good aluminum spool (Hobart, Lincoln, Harris) is usually dead-on.

Stainless Steel Without Turning Blue

Use 308 or 316 tri-mix gas (Heliarc 90/8/2 or similar) if you can get it—way less soot and discoloration. Voltage about the same as mild steel, wire speed 20–40 IPM slower. Keep heat low and travel fast or you’ll sugar the weld.

Real Shop Story: The Day the Chart Saved a $40,000 Repair

I was on a rush job fixing a cracked loader bucket for a quarry in Pennsylvania—3/8″ T1 steel, multi-pass, outside in January. The chart said 25–27 volts and 340 IPM on 0.045″ wire. Kid running second shift ignored it, cranked everything to 11, and burned a 4-inch hole straight through the cheek plate.

Forty-thousand-dollar bucket, two days behind. I walked in, looked at the hole, dropped to 25.5 volts and 360 IPM, laid four perfect passes, and we shipped it that afternoon. The chart doesn’t have feelings—it just works.

Fine-Tuning for Different Positions

Flat and horizontal: Run the upper half of the chart.

Vertical up: Drop wire speed 15–20%, voltage 0.5–1 volt, travel steady.

Overhead: Go even colder—sometimes 2 volts and 50 IPM less. Use 0.035″ instead of 0.045″ if possible; smaller puddle is easier to control.

Pro Tip Most Old Timers Won’t Tell You

Once you find the perfect settings for a certain thickness and wire, write them on a piece of 1/4″ plate with a center punch or engraver and hang it on the wall.

Next time you’re halfway through a job and the machine gets bumped, you’re back welding in ten seconds instead of twenty minutes of guessing.

Conclusion

Print a good MIG welding wire speed and voltage chart, laminate it, and stick it on your welder tomorrow. Start every new thickness or wire change in the middle of the range, run test beads, and tweak until it sings. Do that and I guarantee your welds will look better, penetrate stronger, and you’ll burn half the wire you used to.

Welding stops being a mystery and turns into a skill you control. Grab that scrap, dial it in, and go make something strong enough to last three lifetimes.

The sound never lies. When it sounds like steady bacon frying and the puddle washes in clean on both toes—no undercut, no spatter—you’re there. Trust your ears more than your eyes some days.

Some FAQs

What wire speed for 1/8 mild steel with 0.030 wire?

Start around 19 volts and 240–260 IPM with 75/25 gas. Adjust up or down depending on fit-up and how the arc sounds.

Can I use the same settings for indoor and outdoor welding?

No. Wind kills shielding gas. Outdoors, crank gas flow to 30–40 CFH, run slightly hotter voltage, and keep your stickout short.

Is a MIG chart the same for Lincoln and Miller machines?

Close enough. Miller tends to read about 0.5–1 volt higher for the same arc length. Always verify with test beads.

Do I need different settings for rusty farm steel vs clean hot-rolled?

Absolutely. Mill scale acts like an insulator. Clean it shiny or run 1–2 volts hotter and 30–50 IPM faster to punch through.

Why does my bead look good but fail bend tests?

Cold lap from too low voltage or too slow travel speed. Increase voltage half a volt or slow your wire speed 20 IPM and push the puddle harder into the toes.