Setting the right flux core wire speed and voltage is one of those things that can make welding feel either effortless or frustrating. In real shop work, I’ve seen good welders struggle simply because their machine wasn’t dialed in for the metal thickness or wire size they were using.

That’s why a flux core wire speed and voltage chart is such a go-to reference, especially for beginners and DIY welders running FCAW machines. Too much voltage leads to spatter and burn-through, while too little wire speed causes stubbing, poor penetration, and weak welds.

These settings directly affect arc stability, bead profile, and structural strength. In this guide, I’ll show you how to read a flux core settings chart the right way and adjust it for clean, consistent welds in real-world conditions.

What Makes Flux Core Welding So Popular in Everyday Shops?

Flux core welding, or FCAW if we’re getting technical, is that go-to process when you need portability and don’t want to mess with shielding gas. It’s basically MIG welding’s tougher cousin—self-shielded with a flux-filled wire that protects the weld pool from contaminants.

I’ve used it on everything from outdoor repairs where wind blows away gas to thick structural steel that demands deep penetration.

How it works is straightforward: The wire feeds through your gun, melts in the arc, and the flux inside vaporizes to create a shielding gas and slag layer. This slag is key—it cools the weld and prevents oxidation, but you’ve got to chip it off afterward.

When I first started, I thought it was just “plug and play,” but nope. The magic happens when you match wire speed to voltage for a stable arc.

Use it when you’re working dirty or outdoors, like on construction sites or farm machinery. Why? No gas bottles to haul, and it handles rust better than solid wire MIG. But here’s a shop tip: Always preheat your material if it’s cold—I’ve seen welds crack on chilled steel because the flux couldn’t keep up.

Common mistake? Running too hot on thin gauge, which warps the heck out of your piece. Fix it by dropping voltage and bumping wire speed for a cooler, faster puddle.

In my experience, pros love flux core for its speed on heavy plate, while hobbyists appreciate the forgiveness on imperfect joints.

Just remember, electrode diameter matters—thicker wires like .045″ for beefy jobs, thinner .030″ for sheet metal. Pair that with the right amperage, and you’re golden.

How Do Wire Speed and Voltage Interact in Flux Core Setup?

Wire speed and voltage are like dance partners in flux core welding—they’ve got to sync up or the whole thing falls apart. Wire speed controls how fast the filler metal enters the arc, measured in inches per minute (IPM). Voltage sets the arc length and heat input.

Too much voltage with low speed? You’ll get a wide, shallow bead with spatter everywhere. Low voltage and high speed? Stubbing and poor fusion.

I’ve tinkered with this on my old Lincoln welder countless times. For instance, on 1/4-inch mild steel, I aim for 18-22 volts and 200-300 IPM with .035″ wire. It gives that smooth, buttery arc. When to adjust? If your weld sounds like frying bacon (good), keep it. Popping like fireworks? Crank down voltage.

Practical tip: Start with manufacturer recommendations, then fine-tune based on your machine’s quirks. My shop’s welder runs hot, so I dial back 10% from charts.

Beginners often crank voltage too high, thinking more heat equals better penetration—wrong. It just burns through. Pros? We watch for rod burn-off; if wire stubs before melting properly, slow the speed.

Safety note: Always wear your PPE—flux core throws more spatter, and I’ve got scars from ignoring that. For joint prep, clean edges with a grinder; flux handles some mill scale, but don’t push it.

Decoding a Flux Core Wire Speed and Voltage Chart

Ever stared at one of those charts and felt like it was written in code? I did too, until I broke it down on actual jobs. A flux core wire speed and voltage chart lists recommended settings based on wire diameter, material thickness, position, and sometimes gas type if you’re dual-shielding.

What it is: Essentially a table from wire makers like Lincoln or Hobart, showing voltage ranges (e.g., 15-30V) paired with wire feed speeds (100-500 IPM) and resulting amperage (50-300A).

How to read it: Find your wire size, then match to metal gauge. For flat welding on 3/16″ steel with .035″ wire, it might suggest 20-24V at 250-350 IPM, pulling 150-200 amps.

When to use it: Every setup, but especially on new materials. Why? It prevents undercuts or lack of fusion that lead to weak joints. In the shop, I pull up charts on my phone mid-job—beats scrapping parts.

Tip: Convert IPM to amps if your machine shows one but not the other; roughly, 1 IPM of .035″ wire equals 1 amp.

Anecdote: Once welded a gate with wrong settings—too slow wire, high volts—and it distorted so bad I had to cut it apart. Lesson? Test on scrap first. For pros, tweak for position; overhead needs lower volts to fight gravity.

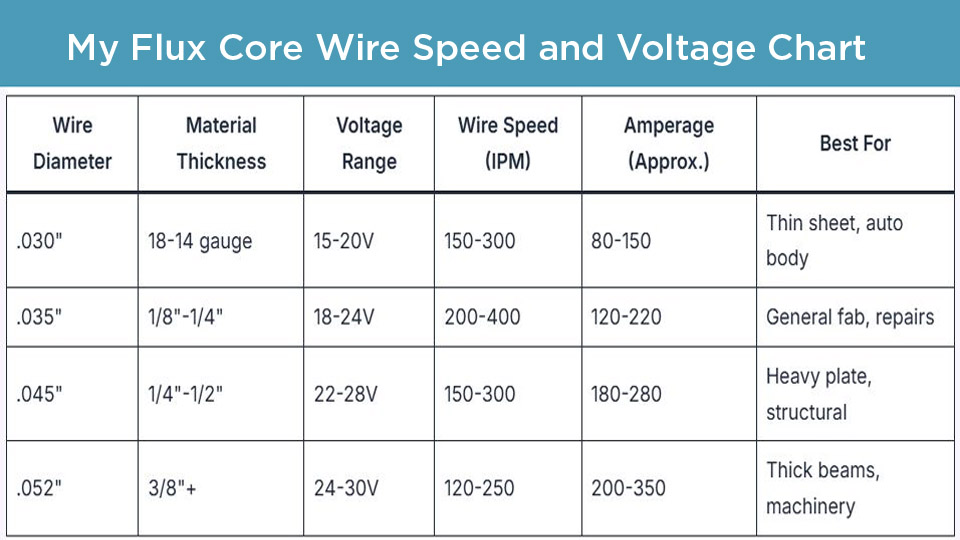

Here’s a simple comparison table for common setups:

| Wire Diameter | Material Thickness | Voltage Range | Wire Speed (IPM) | Amperage (Approx.) | Best For |

|---|---|---|---|---|---|

| .030″ | 18-14 gauge | 15-20V | 150-300 | 80-150 | Thin sheet, auto body |

| .035″ | 1/8″-1/4″ | 18-24V | 200-400 | 120-220 | General fab, repairs |

| .045″ | 1/4″-1/2″ | 22-28V | 150-300 | 180-280 | Heavy plate, structural |

| .052″ | 3/8″+ | 24-30V | 120-250 | 200-350 | Thick beams, machinery |

Pros of using charts: Saves time, reduces waste. Cons: They’re guidelines, not gospel—your machine might vary.

Choosing the Right Flux Core Wire for Your Job

Picking wire isn’t random; it’s about matching to your project. Flux core wires come in types like E71T-1 (all-position, high deposition) or E71T-11 (self-shielded, no gas needed). I’ve stuck with E71T-GS for most DIY stuff—it’s versatile and cheap.

How it works: The “T” means tubular, flux inside. Diameter affects everything; smaller for detail work, larger for fill. When to choose: Thin wire for low amps on sheet, thick for high-heat thick stuff.

Why care? Wrong wire leads to porosity or cracks. Shop tip: Store wire dry; moisture kills flux.

Common mistake: Using gas-shielded wire without gas—hello, bad welds. Fix by switching to self-shielded.

In repairs, like patching exhaust, .030″ at 16V/200 IPM works wonders. For students, start with mild steel; aluminum flux core exists but it’s finicky.

Setting Up Your Machine for Optimal Performance

Machine setup is where theory meets metal. Step-by-step: First, select polarity—DCEN for most flux core (electrode negative). Thread wire, set tension just enough to avoid birdnesting.

How: Dial voltage based on chart, then wire speed to match arc sound. Test bead on scrap. When: Before every job shift.

Why: Prevents downtime from jams. Tip: Clean liner regularly; I’ve lost hours to dirty guns.

Anecdote: On a fence job, ignored tension—wire slipped, ruined a section. Now, I check every time.

For US machines like Miller or Hobart, use their apps for charts. Joint prep: Bevel thick edges for penetration.

Handling Different Materials with Flux Core

Mild steel is flux core’s bread and butter, but what about stainless or galvanized? For stainless, use specific wires like 308LT-1; settings similar but lower volts to avoid burn-through.

How it works: Flux adjusts for alloys. When: Specialty jobs like food equipment. Why: Prevents corrosion.

Tip: On galvanized, grind off zinc first—fumes are nasty. Mistake: Welding over coating; leads to porosity. Fix with anti-spatter.

For aluminum, rare in flux core, but possible with special wire—high speed, low volts.

Troubleshooting Common Flux Core Issues

Spatter city? Undercut edges? I’ve fixed ’em all. Spatter from high volts—drop it. Undercut: Slow travel speed.

How to diagnose: Listen and look. Popping arc? Too low speed. When: Mid-weld, adjust on fly.

Why fix quick: Saves rework. Tip: Use anti-spatter spray liberally.

Anecdote: Beginner me had worm tracks (porosity)—dirty metal. Now, I wire brush everything.

Advanced Techniques for Pro-Level Welds

Once basics are down, stack beads for strength. Multi-pass on thick joints: First pass penetrates, fillers build.

How: Overlap 50%. When: Structural work. Why: Even stress distribution.

Tip: Weave for wide joints, but not too much—distorts. For vertical, uphill with short arcs.

In my shop, we use pulse modes if available, but standard flux core shines in basic setups.

Safety First in Flux Core Operations

Flux core smokes more, so ventilation is non-negotiable. I’ve coughed through bad days—now, extractor fans always.

What: Fumes contain metals; mask up. How: Position fan to pull smoke away.

When: Always. Why: Health over haste.

Tip: Auto-dark helmets save eyes; I’ve upgraded and never looked back.

Back in the day, I skimped on gloves—spatter burns taught me quick.

Comparing Flux Core to Other Processes

Vs. Stick (SMAW): Flux core faster, less skill for continuous beads. But stick better for wind.

Pros: Higher deposition. Cons: More cleanup.

Vs. MIG: No gas hassle, but MIG cleaner indoors.

When to switch: Indoor precision? MIG. Outdoor rough? Flux core.

In fab shops, we mix processes per job.

Wrapping Up

Nailing wire speed and voltage has saved me countless headaches and dollars in scrap. You’re now armed with the know-how to grab a chart, set your machine, and lay down beads that hold up under stress.

Whether it’s a quick fix or a big build, these settings ensure your welds penetrate right, look pro, and last. Always log your successful settings in a notebook—next time a similar job rolls in, you’re not starting from scratch.

FAQs

What voltage should I use for .035 flux core wire on 1/4-inch steel?

Aim for 20-24 volts with 250-350 IPM. This pulls about 150-200 amps for good penetration without burn-through. Test on scrap and listen for that steady sizzle.

How do I adjust wire speed if my welds are too convex?

Convex beads mean too much wire or low travel speed. Bump up your travel or drop wire speed by 50 IPM increments until the bead flattens. Clean slag between tests.

What’s the best flux core setting for overhead welding?

Lower voltage to 18-22V and wire speed to 200-300 IPM for .035″ wire. Short arc to control puddle—practice on vertical first to build confidence.

Why does my flux core welder keep birdnesting?

Usually loose tension or dirty liner. Tighten the drive rolls just enough to feed without slipping, and blow out the liner with compressed air. Check wire spool for kinks too.

Can I use flux core on thin sheet metal without warping?

Yes, with .030″ wire at 15-18V and 150-250 IPM. Use stitch welding—short bursts with cooldowns—and clamp to a heat sink like copper backing.