One of the most common questions that comes up when burning rod is about stick welding rod sizes, especially when welds aren’t turning out the way they should. Running stick isn’t just striking an arc and going—it’s about matching the right electrode diameter to the metal thickness, joint type, and welding position.

Go too big and you risk poor penetration, slag inclusions, or overheating the base metal; go too small and you’re fighting weak welds and wasted time. Compared to MIG vs TIG, stick welding demands tighter arc control and smarter setup, particularly when working outdoors or on structural steel.

Getting rod size right matters for weld quality, structural strength, and even how much cleanup you’re stuck doing afterward. Keep reading, and I’ll break down how to choose the right stick welding rod size for real-world jobs, not just what the chart says.

Understanding Stick Welding Rods and Their Sizes

Stick welding rods are essentially metal cores wrapped in flux coating. That core is what becomes your filler metal, and the flux shields the weld from air contaminants while adding alloys for strength. Sizes refer to the diameter of that core, measured in inches or millimeters, and they range from tiny 1/16-inch rods up to beefy 5/16-inch ones for heavy-duty work.

The diameter isn’t arbitrary—it’s tied to how much current the rod can handle without overheating or underperforming. Smaller rods melt faster with lower amps, making them ideal for delicate jobs, while larger ones need more power for deep penetration on thick materials.

In my shop, I keep a mix on hand because no single size fits every project. For instance, on a farm repair job last summer, I switched from a 3/32-inch rod to a 1/8-inch one midway through to handle varying plate thicknesses without constantly readjusting my machine.

Common sizes you’ll see in US welding supplies include 1/16″, 5/64″, 3/32″, 1/8″, 5/32″, 3/16″, 1/4″, and up to 5/16″. Each has its sweet spot.

The 1/16″ is great for intricate work on thin gauge steel, like auto body panels, where you don’t want excess heat warping the metal. I’ve used them on motorcycle frames, running at around 40-60 amps to keep things controlled.

How Rod Diameter Affects Weld Quality

Diameter influences everything from arc stability to slag removal. A thinner rod gives a narrower bead with less heat input, reducing distortion on sensitive parts. But push it too hard, and it’ll stick or create undercut edges.

I’ve learned the hard way that forcing a small rod on thick stock leads to shallow welds that crack under stress—happened to me on a gate hinge repair that failed after a week.

Larger diameters provide more filler deposition per pass, speeding up jobs on structural beams or pipeline sections. They require higher amps, say 150-200 for a 3/16″ rod, to maintain a smooth arc. The trade-off? More spatter if your technique slips, and they’re tougher to maneuver in tight spots.

Always match the size to your material thickness: as a rule of thumb, the rod should be no larger than half the thickness of the thinnest piece you’re joining.

Decoding Rod Classifications and Sizes

Rods come labeled with codes like E6010 or E7018, where the first two digits indicate tensile strength, and the rest cover position and flux type.

Size is separate but crucial—it’s printed on the box or rod end. For all-position welding, like overhead repairs, smaller sizes flex better without dripping molten metal on your helmet.

In fabrication shops across the States, E6013 rods in 3/32″ are a go-to for beginners because they’re forgiving on rusty metal and run smooth on AC machines. I’ve stocked them for quick fixes on farm equipment, where you might not have time for perfect prep.

Contrast that with E7018 in 1/8″, which I prefer for high-strength applications like trailer builds—low hydrogen to prevent cracking, but it demands dry storage to avoid porosity.

Choosing the Right Stick Welding Rod Size for Your Project

Picking the right size starts with assessing your job. Ask yourself: What’s the material? How thick? What position? What’s my power source? I’ve mentored guys who grab whatever’s handy, only to fight a unstable arc all day. Let’s break it down so you can avoid that.

For mild steel up to 1/8″ thick, stick with 1/16″ or 5/64″ rods. They allow fine control and prevent burn-through. On a recent hobby project—a custom toolbox—I used 5/64″ at 70 amps for clean, flat beads that didn’t warp the sheet.

Thicker stuff, like 1/4″ plate, calls for 1/8″ or 5/32″. These deposit more metal quickly, building strong multi-pass welds. In shop classes, I teach students to start with 1/8″ on practice coupons—it’s versatile for flat, horizontal, and vertical positions.

Rod Size Recommendations by Material Thickness

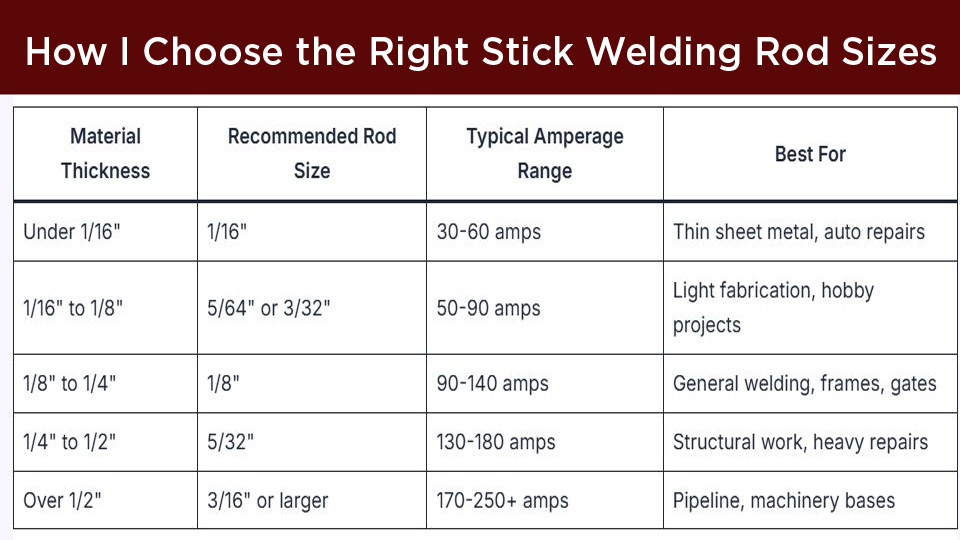

Here’s a quick reference table I’ve put together from years of jobs. It’s not set in stone—adjust for your machine and technique—but it’s saved me trips back to the supply store.

| Material Thickness | Recommended Rod Size | Typical Amperage Range | Best For |

|---|---|---|---|

| Under 1/16″ | 1/16″ | 30-60 amps | Thin sheet metal, auto repairs |

| 1/16″ to 1/8″ | 5/64″ or 3/32″ | 50-90 amps | Light fabrication, hobby projects |

| 1/8″ to 1/4″ | 1/8″ | 90-140 amps | General welding, frames, gates |

| 1/4″ to 1/2″ | 5/32″ | 130-180 amps | Structural work, heavy repairs |

| Over 1/2″ | 3/16″ or larger | 170-250+ amps | Pipeline, machinery bases |

Use this as a starting point. For stainless or aluminum, factor in alloy-specific rods—smaller sizes often work better to control heat on these heat-sensitive metals.

Matching Rod Size to Your Welding Machine

Your welder’s output limits what sizes you can run effectively. Buzz boxes or small inverter machines top out at 140 amps, so stick to 1/8″ max to avoid duty cycle issues. I’ve got an old Lincoln tombstone that hums along with 3/32″ rods all day, but push it to 5/32″ and it overheats on long runs.

Engine-driven welders handle bigger rods no problem—great for field work. Test your setup on scrap: Strike an arc, run a bead, and check for consistent puddle. If it’s digging in too much or not penetrating, bump the amps or switch sizes.

Step-by-Step Guide to Using Different Stick Welding Rod Sizes

Nothing beats hands-on practice, but here’s how I approach it step by step, like showing a trainee.

First, prep your joint: Clean off rust, paint, or oil with a grinder or wire brush. Bevel edges on thick stock for better penetration—45 degrees works for most.

Set your machine: Polarity matters—DC electrode positive for deep welds, AC for general use. Dial in amps based on size: Start low and creep up.

Strike the arc: Tap or scratch method. For small rods, a quick tap prevents sticking; larger ones need a firmer scratch.

Run the bead: Weave or stringer? Smaller rods suit stringers for speed; larger for weaves to fill wide joints. Keep a short arc length—about the rod’s diameter.

Clean slag between passes: Chip it off hot to avoid inclusions. I’ve skipped this in a rush and paid with porous welds that leaked on a tank repair.

Post-weld: Inspect for cracks, undercut. Grind smooth if needed.

Techniques for Small Diameter Rods

With 1/16″ or 3/32″, focus on steady travel speed to avoid piling up metal. I use a slight drag angle—10-15 degrees—to push the puddle. On vertical ups, short whips keep it from sagging.

Common mistake: Too much heat warps thin stuff. Solution: Tack frequently and let cool between passes. In my garage, I keep a fan handy for quick cooling on sheet work.

Handling Larger Rod Sizes Effectively

For 5/32″ and up, crank the amps and use a push angle for better flux coverage. These rods love a steady weave—figure-eight pattern for even fill.

Pitfall: Overheating the rod end causes flux to flake off prematurely. Fix: Store rods dry and use oven if low-hydrogen type. I’ve rescued damp rods by baking them at 250°F for an hour.

Common Mistakes with Stick Welding Rod Sizes and How to Avoid Them

Even seasoned welders slip up. One biggie: Using oversized rods on thin metal. It blasts holes faster than you can say “oops.” Stick to smaller diameters and lower amps.

Undersizing leads to weak, shallow welds. I once undersized on a loader bucket repair—held for a day, then split. Lesson: Match to the thickest part.

Ignoring rod type with size: A 1/8″ E6010 digs deep for root passes, but E7018 in the same size is for fills. Mix them wrong, and your joint fails inspection.

Storage blunders: Rods absorb moisture, causing hydrogen cracks. Keep them in sealed cans or rod ovens. I’ve lost batches to humid shop air—now I check dates and conditions.

Technique errors: Long arcs with small rods create spatter city. Shorten it up. For larges, rushing the weave leaves cold laps—slow down for full fusion.

Safety Considerations When Working with Various Rod Sizes

Safety’s non-negotiable—I’ve seen burns and flashes that sidelined guys for weeks. Smaller rods produce finer spatter that sneaks under collars; wear full leathers.

Larger rods mean hotter arcs—bigger UV risk. Always use a #10-12 lens, and shield bystanders.

Fumes from flux: Ventilate, especially with alloy rods. I use a extractor fan in tight spaces.

Electrical: Ground properly to avoid shocks. Damp rods increase risk—dry them out.

Lifting: Heavy rod boxes strain backs. Use carts in the shop.

Advanced Tips for Optimizing Stick Welding Rod Sizes in Fabrication

Once basics click, experiment. For multi-pass welds, start with smaller rods for roots, then larger for caps—better control and fill.

On alloys: Stainless likes 3/32″ for precision; cast iron needs nickel rods in 1/8″ for machinability.

Field hacks: No oven? Heat rods with a torch lightly. Not ideal, but beats porosity on remote jobs.

Cost-saving: Buy in bulk for common sizes, but rotate stock to avoid expiration.

Machine tweaks: Add a rectifier for smoother DC on AC machines with small rods.

Pros and Cons of Popular Rod Sizes

Let’s weigh them out.

For 3/32″:

Pros: Versatile, low amp requirement, easy start.

Cons: Slower deposition, more passes on thick stock.

For 1/8″:

Pros: Balances speed and control, great for most jobs.

Cons: Needs decent power, can warp thin metal.

For 5/32″:

Pros: Fast fill, deep penetration.

Cons: Heavy spatter if mishandled, harder in positions.

Joint Preparation and Rod Size Compatibility

Prep dictates size. Butt joints on thin plate? Small rod, square edges.

T-joints on heavy? Larger rod, fillet with bevel.

Cleanliness: Mill scale resists small rods—grind it off.

Gap filling: Undersized rods bridge better, but don’t overdo.

Real-World Applications: Stick Welding Rod Sizes in Action

In auto repair: 1/16″ for exhaust—quick, low heat.

Construction: 3/16″ for rebar—strong, fast.

Hobby: 3/32″ for sculptures—fine detail.

Farm: 1/8″ for implements—durable against abuse.

Pipeline: 5/32″ E6010—deep roots in all positions.

I’ve welded submarine parts with precision small rods—tight tolerances.

Conclusion

After reading this article, you’ve now got the lowdown on stick welding rod sizes from someone who’s lived it—sizes that match your job for stronger, safer welds without the guesswork. Whether you’re a DIYer fixing your grill or a pro on a skyscraper skeleton, choosing the right diameter means less rework, better integrity, and confidence in your work.

Always run a test bead on scrap matching your project material before committing—it’ll reveal if your size and settings are spot-on, saving you from costly do-overs. Get out there, strike an arc, and build something solid.

FAQs

What size stick welding rod should I use for thin metal?

For metal under 1/8″ thick, go with 1/16″ or 5/64″ rods to avoid burn-through. Run low amps, say 40-70, and use quick tacks to control heat. I’ve saved many thin panels this way in bodywork.

How do I know if my welding rod is too big for the job?

If you’re getting excessive spatter, poor penetration, or the arc feels unstable, it’s likely oversized. Drop down a size and adjust amps up slightly—test on scrap to confirm fusion without holes.

Can I use the same rod size for different materials?

Not always—mild steel tolerates versatility, but stainless or aluminum needs specific alloys in matching sizes. For cast iron repairs, 1/8″ nickel rods work wonders, but stick to smaller for aluminum to manage heat.

What’s the best way to store different sizes of welding rods?

Keep them dry in sealed containers or a rod oven at 250°F for low-hydrogen types. Sort by size in labeled bins—I use old ammo cans in my shop to prevent mix-ups and moisture pickup.

Why does my weld crack with certain rod sizes?

Cracks often stem from hydrogen in damp rods or mismatched sizes causing stress. Use smaller rods for better control on high-strength steels, and always preheat thick sections to 200°F before welding.