Getting the TIG welding amps matched to metal thickness is one of the biggest factors in how clean and controllable your weld turns out. I’ve had plenty of welds where the puddle either wouldn’t form because the amps were too low, or it got way too fluid and overheated the joint when the amps were too high.

Whether you’re welding stainless steel, mild steel, or aluminum, the right amperage depends on thickness, joint prep, and how you control the welding torch and filler rod. A lot of welders ask the same question: How many amps should I use for this thickness? That’s exactly why a reliable TIG welding amps to metal thickness chart is such a valuable tool.

Dialing this in improves arc control, penetration, bead appearance, and overall weld strength — while saving time and preventing costly rework. In this guide, I’ll break down a practical amp-to-thickness chart and show you how to fine-tune it for real-world TIG welding results.

What is TIG Welding and Why Does It Demand Precise Amp Control

TIG welding, or Tungsten Inert Gas welding as it’s formally known, is my go-to process for precision work. It uses a non-consumable tungsten electrode to create an arc, with inert gas shielding the weld pool from contamination.

Unlike MIG, where the wire feeds automatically, TIG requires you to manually add filler rod, giving you ultimate control over the bead.

But here’s the kicker: amps are the heartbeat of your TIG setup. They dictate the heat input, which directly affects penetration and fusion.

Too much heat from high amps warps thin metals or causes undercut, while insufficient amps lead to lack of fusion and cold laps. In my experience, understanding this balance has saved me from scrapping expensive stainless sheets more than once.

Think about it in a shop setting—say you’re welding aluminum bike parts. If your amps aren’t matched to the thickness, you risk oxide contamination or incomplete welds that could fail during a ride.

Precision here isn’t just about aesthetics; it’s about reliability, especially under US welding codes like those from AWS that emphasize joint strength.

From a practical standpoint, TIG shines in applications needing clean finishes, like food-grade stainless tanks or aircraft components. I’ve used it on everything from 16-gauge sheet metal to 1/4-inch plate, and each time, starting with the right amp range makes the difference between a smooth session and a frustrating one.

Decoding the TIG Welding Amps to Metal Thickness Chart

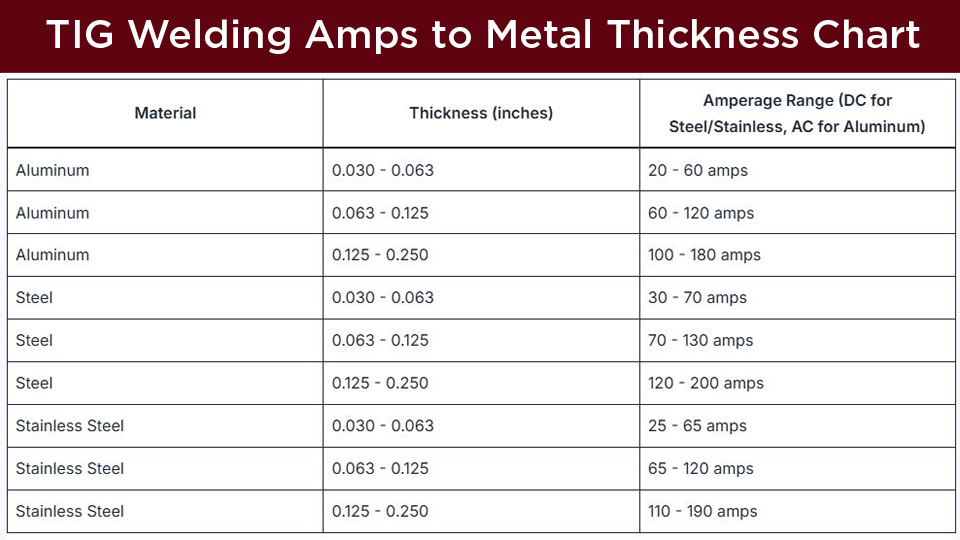

Let’s get to the meat of it: the tig welding amps to metal thickness chart. This isn’t some one-size-fits-all magic number; it’s a starting point based on material type, joint configuration, and your machine’s capabilities. I’ve compiled this from countless jobs, adjusting for real-world factors like AC vs. DC polarity and gas flow.

For aluminum, which loves AC for cleaning action, amps ramp up with thickness to ensure proper penetration without excessive heat. Steel and stainless, often on DC, need less amps comparatively because they conduct heat differently.

Here’s a basic chart I use as a reference in my workshop. Remember, these are approximate for manual TIG with argon shielding—test on scrap first.

| Material | Thickness (inches) | Amperage Range (DC for Steel/Stainless, AC for Aluminum) |

|---|---|---|

| Aluminum | 0.030 – 0.063 | 20 – 60 amps |

| Aluminum | 0.063 – 0.125 | 60 – 120 amps |

| Aluminum | 0.125 – 0.250 | 100 – 180 amps |

| Steel | 0.030 – 0.063 | 30 – 70 amps |

| Steel | 0.063 – 0.125 | 70 – 130 amps |

| Steel | 0.125 – 0.250 | 120 – 200 amps |

| Stainless Steel | 0.030 – 0.063 | 25 – 65 amps |

| Stainless Steel | 0.063 – 0.125 | 65 – 120 amps |

| Stainless Steel | 0.125 – 0.250 | 110 – 190 amps |

This chart assumes a 1/16-inch tungsten for thinner stock and 3/32-inch for thicker. For butt joints, stay on the lower end; fillets might need a bump up for better fill.

In practice, I always start 10-20% below the chart and pedal up as needed. One time, on a 1/8-inch aluminum manifold, I ignored humidity’s effect and started too high—ended up with a warped piece.

Lesson learned: charts guide, but your eyes and torch hand refine.

TIG Welding Settings for Aluminum

Aluminum is tricky because of its oxide layer and high thermal conductivity. You need AC polarity to break through that oxide, and amps must match thickness to avoid puddles that are too hot or too cold.

For thin aluminum like 0.040-inch sheet, I set around 40-50 amps to start, using pure argon at 15-20 CFH. This gives a stable arc without burn-through. On thicker 3/16-inch plate, crank it to 140-160 amps for deep penetration.

Prep is key: clean with a stainless brush dedicated to aluminum to prevent contamination. I once skipped this on a boat repair and got black sooty welds—total do-over.

Practical tip: Use a foot pedal for fine control. Start low, build the puddle, then add filler like 4043 rod smoothly. For hobbyists, this setup works great on inverters like those from Lincoln or Miller, common in US garages.

TIG Welding Settings for Steel

Steel is more forgiving than aluminum, running on DC electrode negative for concentrated heat. For 16-gauge (about 0.060-inch), 60-80 amps does the trick with ER70S-6 filler.

On heavier carbon steel, say 1/4-inch, I’ll go 150-180 amps to fuse properly without porosity. Always back-purge if welding pipe to avoid sugaring inside.

In my shop, we’ve welded truck frames where mismatched amps led to cracks under vibration. Stick to the chart, but factor in joint type—tee joints need more heat than laps.

Tip for students: Practice on scrap with varying thicknesses. You’ll feel when the puddle flows right, like butter on a hot pan.

TIG Welding Settings for Stainless Steel

Stainless demands care to preserve corrosion resistance. Use DC for most, with amps slightly lower than carbon steel due to its alloys.

For 0.050-inch 304 stainless, 50-70 amps with 308L filler keeps distortion minimal. Thicker 1/8-inch might need 100-140 amps.

Heat input is critical—too high and you lose chrome, inviting rust. I learned this the hard way on a brewery tank; over-amping caused discoloration that required pickling.

Pro advice: Use argon-helium mix for thicker stock to boost penetration without cranking amps too high. Flow at 10-15 CFH to save gas costs.

Factors That Influence Your TIG Amp Settings

Amps aren’t isolated; they’re influenced by polarity, gas type, electrode prep, and even ambient temperature. AC for non-ferrous, DC for ferrous—that’s basics.

Joint prep matters: Bevel edges on thick stock for better fusion, which might allow lower amps. Dirty metal? It’ll require more heat to burn through contaminants.

Machine type plays in—older transformers need higher amps than modern inverters, which are more efficient. In humid US summers, add 10% amps to compensate for slower puddle formation.

Personal anecdote: On a windy outdoor job, drafts blew away shielding, forcing amp increases. Always shield your arc properly.

Selecting the Right Tungsten Electrode for Your Amps

Tungsten choice ties directly to amps. I prefer 2% lanthanated (gold tip) for versatility across AC/DC.

For low amps on thin metal, 1/16-inch diameter handles up to 150 amps without overheating. Thicker work? 3/32-inch for 200+ amps.

Grind to a point for DC, balled for AC aluminum. Dull points cause wandering arcs—sharpen longitudinally for stability.

Chart for reference:

| Electrode Diameter (inches) | Max Amps (DC) | Max Amps (AC) |

|---|---|---|

| 1/16 | 150 | 120 |

| 3/32 | 250 | 190 |

| 1/8 | 400 | 300 |

Avoid thoriated if possible due to radioactivity concerns in US regs—ceriated or lanthanated are safer alternatives.

Shielding Gas Choices and Optimal Flow Rates

Argon is king for most TIG, providing stable arcs at 10-20 CFH. For aluminum over 1/4-inch, add helium for hotter arcs without amp spikes.

Flow too low? Oxidation ruins the weld. Too high? Wastes gas and creates turbulence.

In my experience, a gas lens helps distribute flow evenly, especially on stainless where purity is key. Set regulators accurately—I’ve seen pros overlook this and get porous beads.

For cost efficiency in a hobby shop, stick to argon; it’s widely available at US suppliers like Airgas.

Common Mistakes with TIG Amp Settings and How to Fix Them

One big blunder: Ignoring material thickness and blasting high amps on thin stock. Fix: Always measure with calipers and reference your chart.

Another: Not adjusting for filler rod size. Thick rod needs more heat—match it to amps.

Beginners often forget post-flow gas, leading to contaminated tungstens. Set 10-15 seconds to cool properly.

I once over-amped stainless, causing carbide precipitation—lesson: Monitor heat tint and back off if it turns straw-colored.

Step-by-Step Guide to Dialing In Your TIG Welder

First, select material and measure thickness. Reference the amps chart.

Second, choose tungsten: Grind fresh, insert into torch.

Third, set polarity: AC for Al, DC for others.

Fourth, gas up: Argon at 15 CFH, adjust cup size.

Fifth, amps: Start low, test on scrap. Pedal control for variaiton.

Sixth, strike arc, build puddle, add filler rhythmically.

Seventh, inspect: Look for uniform bead, no undercuts.

This process has served me on jobs from fence repairs to custom exhausts.

Practical Workshop Tips for Better TIG Welds

Keep your torch angle at 15-20 degrees for good visibility. Travel speed: Slow on thick, faster on thin to avoid overheating.

For pulse TIG on modern machines, set 50% background amps to control heat input.

Organize your shop—dedicated brushes for metals prevent cross-contamination.

Hobbyists: Invest in a good helmet with true color lens for better arc viewing.

Pro tip: Practice stringer beads daily; it’s the foundation for stack dimes.

Safety First in TIG Welding Operations

Never skimp on PPE: Leather gloves, jacket, auto-darkening helmet rated for TIG.

Ventilate—ozone from UV can irritate lungs. Use fume extractors in enclosed shops.

Electrical safety: Ground properly to avoid shocks, especially with HF start.

In US workplaces, follow OSHA guidelines; I’ve seen fines for improper setups.

Eye protection is non-negotiable—TIG’s bright arc can cause flash burns quickly.

Conclusion

You’ve now got a solid grasp on the tig welding amps to metal thickness chart and how to apply it in your projects. From selecting the right settings for aluminum, steel, or stainless to avoiding common pitfalls, you’re better equipped to create welds that are strong, clean, and efficient.

This knowledge not only boosts your confidence but also ensures safer, more cost-effective work whether you’re in a home garage or pro fab shop. Always keep a log of your successful settings for each material—it’s like building your personal cheat sheet that saves time on future jobs.

How many amps do I need for TIG welding 1/8-inch aluminum?

For 1/8-inch aluminum, aim for 100-140 amps on AC with pure argon. Start low to form the puddle, then adjust with your pedal for clean penetration without burn-through. Test on scrap to fine-tune.

What’s the best tungsten for high-amp TIG on stainless steel?

Go with 2% lanthanated tungsten in 3/32-inch diameter for amps over 150. It holds a point well on DC and resists contamination, making it ideal for prolonged stainless work.

Why are my TIG welds porous even with the right amps?

Porosity often stems from poor shielding—check gas flow (15-20 CFH), clean your metal thoroughly, and ensure no drafts. Also, verify your filler rod isn’t contaminated.

Can I use the same amp settings for DC and AC TIG?

No, AC typically requires 20-30% more amps than DC for similar thicknesses due to the cleaning cycle. Always reference material-specific charts and polarity.

How does metal prep affect TIG amp requirements?

Dirty or oxidized metal demands higher amps to break through, but it’s better to clean first with acetone or a brush. Proper prep lets you stick to lower, more controlled settings for better weld quality.