One of the most common questions I hear in the shop is how many amps to run for a certain metal thickness—and it’s usually right after someone burns through a thin plate or lays down a cold, weak bead. That’s why a welding amps to metal thickness chart is such a valuable reference for both beginners and experienced welders.

Amperage directly controls heat input, penetration, and arc stability, whether you’re stick welding, running MIG or flux core, or even comparing setups to TIG welding.

Set the amps too high and you risk burn-through and distortion; too low and you end up with poor fusion and lack of strength. These settings matter for weld quality, safety, and long-term durability.

In this guide, I’ll show you how to use an amps-to-thickness chart properly and adjust it for real-world welding conditions.

Understanding the Basics of Amperage and Metal Thickness

Amperage is the current flowing through your electrode, basically the power behind your arc. It’s what melts the metal and filler to create that fusion.

Too low, and you get shallow penetration—your weld might look okay on the surface but snap under load. Too high, and you’re dealing with burn-through, especially on thinner sheets, or excessive heat that warps the piece.

The welding amps to metal thickness chart ties this directly to how thick your base metal is. Thinner metals need lower amps to prevent holes and distortion, while thicker ones require more juice for proper penetration.

I’ve used these charts on everything from 16-gauge sheet metal for auto body work to 1/2-inch plate for structural beams. It’s all about balance: enough heat to fuse without destroying the material.

Think of it like cooking a steak—you wouldn’t blast it on high heat if it’s thin, or it’d char before cooking through. Same here.

In practice, charts vary slightly by process, like stick welding (SMAW) versus MIG, but the principle holds. For SMAW, which I use a lot for outdoor repairs, amps range from 40-225 depending on electrode size and metal gauge.

Why bother with this? Safety first—wrong amps can cause rod sticking, leading to arc strikes that damage your machine or start fires.

Then there’s efficiency: proper settings mean less rework, saving time and rods. I’ve seen pros waste hours grinding out bad welds because they eyeballed the amps instead of consulting the chart.

In my shop, I keep a laminated chart taped to the welder. It lists metal thickness in inches or gauges, matched to amp ranges for common electrodes.

For example, on 1/8-inch mild steel, you’d run 90-140 amps with a 3/32-inch rod. Adjust for position—overhead welding needs lower amps to fight gravity.

How Amperage Affects Your Weld Quality

Amperage controls heat input, which dictates bead shape, penetration depth, and spatter levels. Low amps give a narrow, convex bead with poor fusion—common on thick metals where the arc doesn’t dig in. High amps flatten the bead, increase penetration, but risk undercutting edges or creating porosity from rapid cooling.

I’ve learned this the hard way on a trailer frame job. Ran too hot on 1/4-inch steel, and the weld distorted the frame, throwing off alignment. Dropped the amps by 20, and it laid down smooth. The chart helps predict this: for 1/4-inch, aim for 120-180 amps on a 1/8-inch electrode.

Use it when switching materials or positions. Flat welding allows higher amps for speed; vertical needs 10-20% less to avoid sagging. Why? Gravity pulls molten metal down, so lower heat keeps it in place.

Practical tip: Always test on scrap first. Dial in midway on the chart’s range, run a bead, and inspect. If it’s stacking up without penetrating, bump up amps. If it’s burning through, dial back. This shop-floor habit has saved me countless headaches on client jobs.

Choosing the Right Electrode for Your Job

Electrodes are your filler metal, coated for arc stability and slag protection. Size matters—diameter affects amp capacity and deposition rate. Thinner rods for low amps on thin metal; thicker for high amps on heavy stuff.

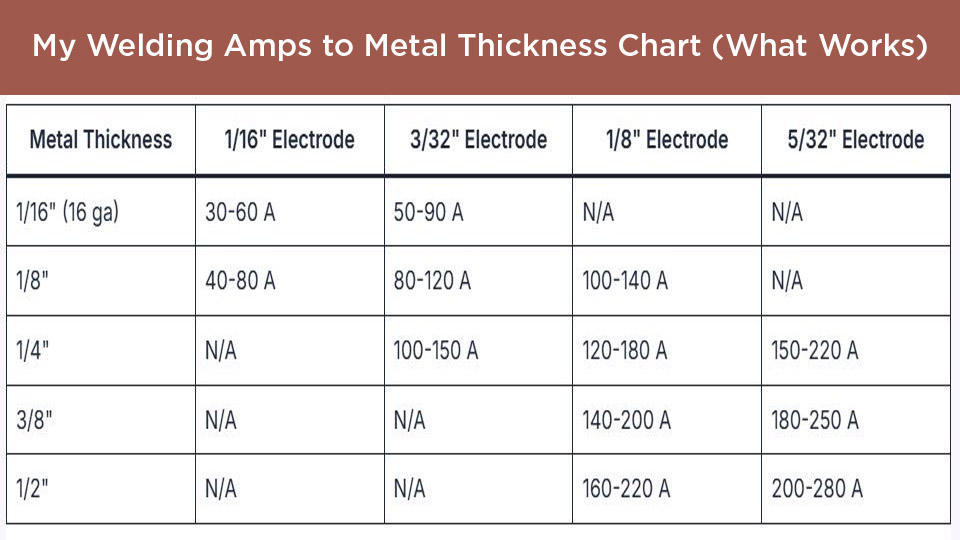

The chart links electrode diameter to thickness. For 16-gauge (about 1/16-inch), a 1/16-inch rod at 30-60 amps works best. Jump to 3/8-inch plate, and you’re looking at 5/32-inch rod at 150-220 amps.

How does it work? Larger diameters carry more current without overheating, allowing deeper penetration. But they’re harder to maneuver on thin stock—I’ve burned holes trying a 1/8-inch rod on 10-gauge.

Choose based on process and material. SMAW rods like E6010 for deep penetration on dirty steel, or E7018 for clean, high-strength welds. Always match to your machine’s output—most US hobby welders are 110V, topping at 140 amps, so stick to smaller rods.

Matching Electrode Diameter to Metal Thickness

This is where the chart shines. It’s a quick reference: list thicknesses down one side, diameters across the top, amps in the cells.

For mild steel:

| Metal Thickness | 1/16″ Electrode | 3/32″ Electrode | 1/8″ Electrode | 5/32″ Electrode |

|---|---|---|---|---|

| 1/16″ (16 ga) | 30-60 A | 50-90 A | N/A | N/A |

| 1/8″ | 40-80 A | 80-120 A | 100-140 A | N/A |

| 1/4″ | N/A | 100-150 A | 120-180 A | 150-220 A |

| 3/8″ | N/A | N/A | 140-200 A | 180-250 A |

| 1/2″ | N/A | N/A | 160-220 A | 200-280 A |

Adjust for alloys—stainless needs 10-15% less to avoid carbide precipitation.

When to use: On repairs, match to the thinnest part to prevent burn-through. Why? Uneven thickness, like patching a pipe, risks weakening the thin side.

Tip: Store rods dry to prevent hydrogen cracking. I’ve had batches go bad from moisture, causing porous welds even at perfect amps.

Common Electrode Types and Their Amp Ranges

E6013 is forgiving for beginners, running 50-160 amps on thin to medium stock. Great for sheet metal fab.

E7018, my go-to for structural, handles 70-225 amps. Low-hydrogen coating means cleaner welds, but needs oven storage.

For pipe, E6010 digs deep at 40-140 amps, ideal for root passes on thick walls.

Pros of matching type: Better mechanical properties, less spatter. Cons: Specialty rods cost more, and wrong type leads to cracking.

Anecdote: Once used E6013 on high-tensile steel—weld held initially but failed under load. Switched to E7018, problem solved. Lesson: Check material specs first.

Setting Up Your Welder for Different Materials

US machines like Lincoln or Miller have amp dials or digital settings. Start with the chart, then fine-tune based on arc sound—a steady sizzle means good; crackling indicates issues.

For mild steel, common in shops, use the table above. Joint prep: Bevel edges on thick stock for better penetration.

Aluminum needs AC or high-frequency TIG, but for stick, special rods like 4043 at 80-200 amps. Clean oxide layer first—I’ve skipped that and got black, porous welds.

Welding Mild Steel: Amps and Thickness Guidelines

Mild steel is forgiving. On 3/16-inch, run 100-160 amps with 1/8-inch rod. Flat position for max speed.

Step-by-step: Clean metal, set amps mid-range, strike arc, maintain 1/8-inch gap, weave if needed for wide joints.

Common mistake: Ignoring polarity. DCEN for shallow, DCEP for deep. I’ve fixed many weak welds by flipping to DCEP.

Why use the chart here? Prevents distortion on frames or panels—high amps warp thin steel.

Tip: For multi-pass, lower amps on fills to build without overheating.

Handling Stainless Steel and Aluminum

Stainless requires lower amps to prevent sensitization— for 1/8-inch, 70-120 amps with 308L rod.

Aluminum: Tricky due to conductivity. 1/8-inch needs 100-150 amps, but preheat to 200°F for thick pieces.

Pros: Corrosion resistance. Cons: More prep, higher cost.

In shop, I weld stainless exhausts—wrong amps cause warping, fixed by pulsing heat.

Joint prep: V-groove for thick, square for thin. Filler match: Use same grade to avoid galvanic corrosion.

Practical Tips for Avoiding Common Mistakes

Beginners over-amp, causing burn-through. Pros under-amp on thick, leading to cold laps.

Fix: Break and re-weld, but prevent with tests.

Overheating and Distortion: How to Prevent It

Distortion comes from uneven heating. Use clamps, tack welds, and staggered passes.

On a gate job, high amps bowed the frame—fixed by peening while hot.

Tip: Lower amps 10% on long runs, let cool between passes.

Undercutting and Lack of Penetration Fixes

Undercutting: Edges melt away from high travel speed. Slow down, adjust angle.

Lack of penetration: Increase amps or bevel deeper.

I’ve ground out undercuts on brackets, wasting time—better to chart-check first.

Step-by-step fix: Grind defect, re-prep, weld at corrected amps.

Step-by-Step Guide to Using the Chart in Real Projects

- Measure thickness with calipers—don’t guess.

- Identify material and process.

- Select electrode diameter from chart.

- Set amps mid-range.

- Prep joint: Clean, bevel if over 1/4-inch.

- Test bead on scrap.

- Weld, monitoring arc.

- Inspect: Use dye penetrant for cracks.

For a repair: Patching 1/4-inch trailer—charted 140 amps, 1/8-inch rod. Perfect fusion.

On fab: Building shelves from 1/8-inch angle—100 amps, no warp.

Pros: Consistent results. Cons: Charts are guides; experience tweaks them.

Anecdote: Trainee ignored chart, burned through—taught him to respect it.

Safety: Always PPE—gloves, helmet. Wrong amps increase flash risk.

I’ve clocked thousands of hours, and this approach cuts failures.

Wrapping Up

Nailing the amps-to-thickness matchup transforms frustrating sessions into smooth, productive ones. You’ve got the tools now to pick the right settings, spot mistakes early, and turn out welds that last. It empowers you to tackle tougher jobs confidently, whether it’s a quick fix or full build.

Always dial in your machine on a fresh rod—old ones can throw off your arc and waste your perfect chart setup.

FAQs

What amps should I use for welding 1/4-inch steel?

For 1/4-inch mild steel with SMAW, go 120-180 amps on a 1/8-inch electrode. Start mid-range, adjust based on penetration. Bevel edges for better fusion on butt joints.

How do I choose the right electrode size for thin metal?

Match to thickness—1/16-inch rod for 16-gauge at 30-60 amps. Avoid larger diameters; they’ll burn through. Test on scrap to confirm no holes.

Why does my weld distort on thin sheets?

High amps cause excessive heat. Drop to the low end of the chart, use skip welding, and clamp pieces. Let cool fully between passes.

Can I use the same amp settings for aluminum as steel?

No—aluminum needs lower amps, around 100-150 for 1/8-inch, with special rods. Clean thoroughly and use DCEP polarity for stability.

What’s a common mistake with amp charts?

Ignoring position—overhead needs 10-20% less amps than flat. Always factor in gravity to prevent drips or weak beads.